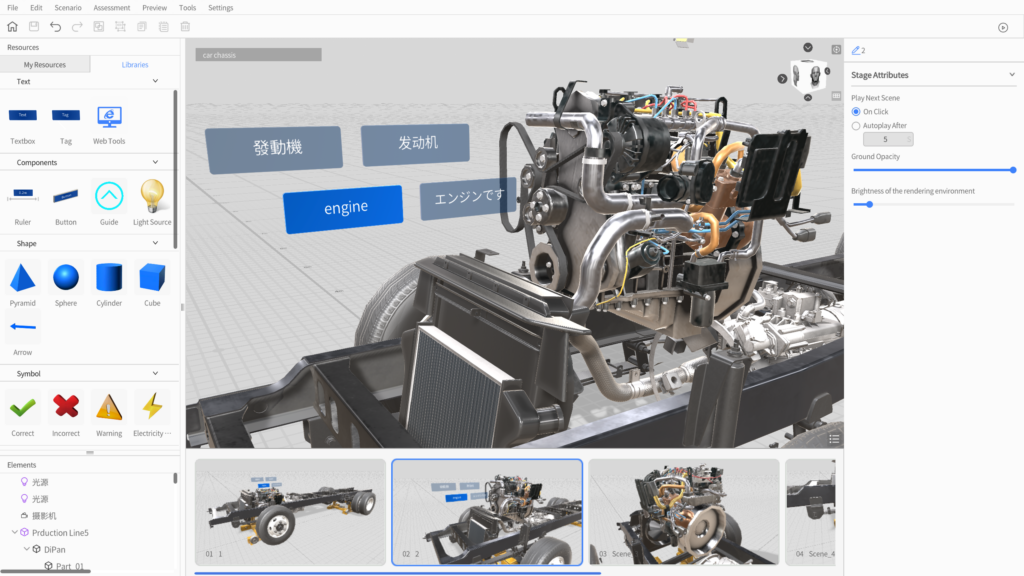

DataMesh Director 7.0 Released: Introducing Training Mode & FAI for One-Click Multi-Language Scenarios!

The new Training Mode in version 7.0 integrates seamlessly with the original DataMesh Learn solution. The highly anticipated multi-language translation feature is now available. Additionally, version 7.0 enhances the user experience on Quest 3 and Vision Pro platforms.

DataMesh Simulator 2.2 Released for Enhanced Immersive Training

Integrating with DataMesh Learn, Simulator create a truly immersive, digital twin-based simulation training experience for manufacturers of heavy machinery, mining equipment, special vehicles, and aircraft, as well as vocational institutions, covering courseware creation, training, and assessment.

DataMesh Concludes New Funding Round

Expediting the research & development efforts and market expansion of DataMesh’s Industrial Metaverse platform, further driving digital transformation across the industrial sector, particularly through the application of XR and digital twin technologies.

DataMesh to Advance Digital Twin and XR Accessibility with New Updates to the FactVerse Platform

Utilising the cutting-edge capabilities of the Snapdragon Spaces™ XR Developer Platform, DataMesh introduces a diverse range of applications to various AR glasses and tablets globally, delivering unmatched XR experiences for enterprise users.

DataMesh FactVerse Updates Released for Industrial Digital Twin Innovation

Enhancements across the entire FactVerse ecosystem to support enterprise users in constructing digital twin scenarios, fostering symbiotic virtual and real environments, and seamlessly integrating with business applications.

DataMesh Contributes to Success of SMART MANUFACTURING SUMMIT

Collaborating with Aichi Prefecture Government and KDDI, DataMesh contributes to the summit by creating an immersive digital industrial landscape based on MR technology, enhancing the attendee experience for the SUMMIT driving Industry 5.0 and innovation between Japan and Europe.

FactVerse Express Opens for Global Creators to Innovate in XR Amid Spatial Computing Trend

FactVerse Express is compatible with Apple Vision Pro, ready to empower users across platforms with an exceptional spatial computing experience upon the availability of Apple Vision Pro, in addition to its existing support for various devices, including Meta Quest 3, iPhone, and iPad.

DataMesh Reshapes Tower Crane Training Experience with Simulator 2.1

Simulator 2.1 introduces brand-new simulation-based training and assessment experience tailored for tower crane operations, through upgraded operational scenarios that faithfully replicate real equipment models, construction environments, and operational procedures.

DataMesh Inspector 1.1 Releases, Enhancing Collaboration and MR Experience in AEC

Streamlining and optimizing key aspects, including visualization, on-site collaboration, and resource management, Inspector empowers construction and engineering professionals to achieve higher project execution efficiency throughout the AEC lifecycle.

DataMesh Director 6.1 Released, Now Supporting Lenovo ThinkReality VRX

Pushing the boundaries of 3D+XR process design and enterprise training, DataMesh Director is now compatible with Lenovo ThinkReality VRX through the Snapdragon Spaces XR developer platform.