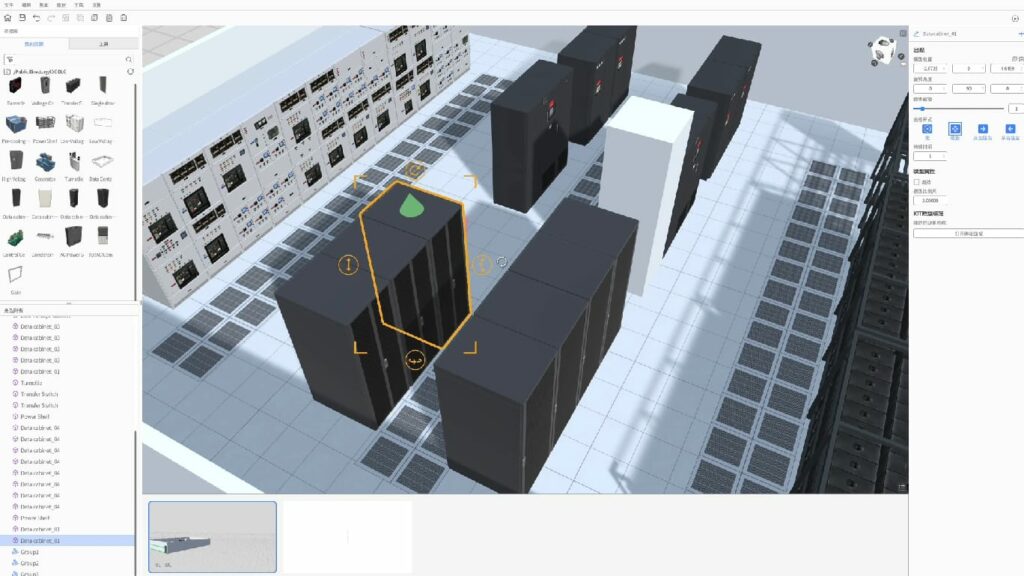

Introducing the new IDC DLC: Build Your Digital Twin Data Center with Ease

The new IDC DLC offers a rich library of standard 3D models commonly used in the IDC industry. Combined with the FactVerse platform’s powerful data tools, it supports key use cases like energy monitoring, temperature & humidity control, power optimization, and anomaly detection—ensuring safe and efficient operations.

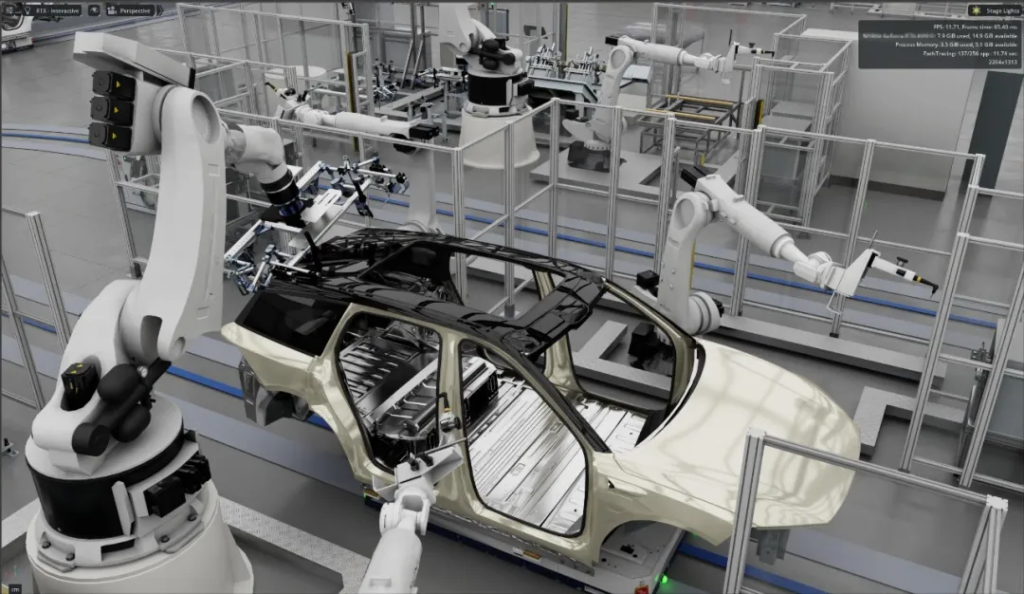

DataMesh Showcases Simulation Digital Twins Powered by DataMesh FactVerse and NVIDIA Omniverse at GTC 2025

FactVerse to further support enterprises to build high-quality simulation digital twins and AI solutions with NVIDIA Omniverse technologies, and introduce a new NVIDIA Omniverse extension, to seamlessly connect FactVerse to applications developed on Omniverse.

DataMesh Director New Version Released! Major Upgrades to Training Mode

The latest version streamlines the courseware creation process with templated question formats, introduces a new Key Question mechanism to enhance risk management in high-risk industrial training scenarios, along with an invigilation feature that enables real-time monitoring of student performance.

FactVerse + Omniverse: Building a Spatiotemporally Consistent Simulation Digital Twin and AI Business Platform

DataMesh is now working closely with NVIDIA to integrate the strengths of FactVerse and NVIDIA Omniverse, making the deployment of digital twins more efficient, sustainable, and user-friendly. This collaboration aims to empower key stages of manufacturing, ultimately enhancing operational efficiency.

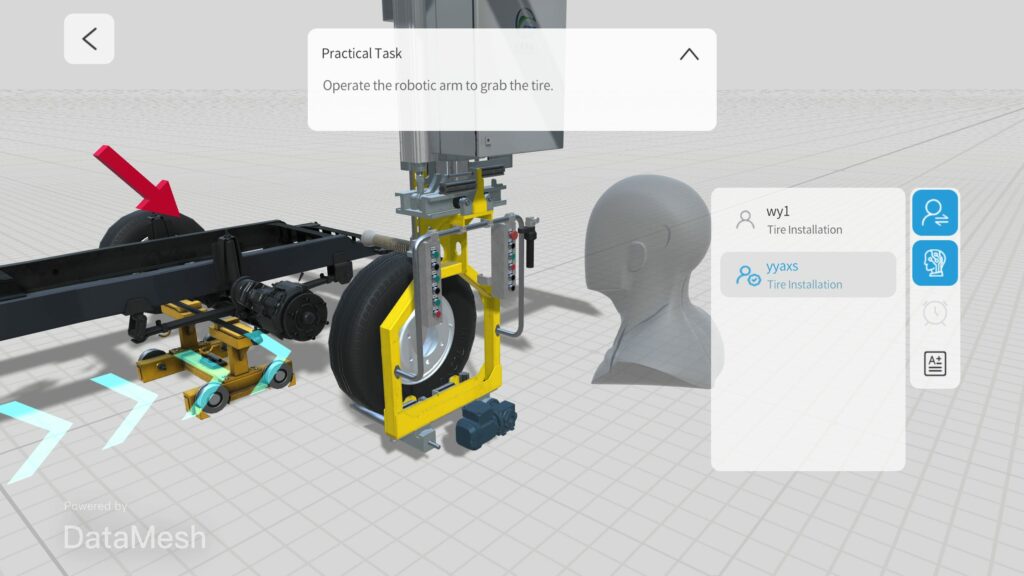

DataMesh FactVerse Supports Foxconn to Enhance Employee Training and Equipment Maintenance Efficiency

With the support of DataMesh FactVerse platform and Apple Vision Pro, Foxconn enables its frontline employees to easily create mixed-reality training materials and inspection plans, and complete training and inspection tasks in a simpler and more intuitive way, resulting in significant improvements in work performance.

DataMesh Recognized as a Sample Vendor in the 2024 Gartner® Emerging Tech Impact Radar Reports

We believe that being named a Sample Vendor in both Simulation Data and Spatial-Based Digital Twins is a testament to the value of DataMesh and the company’s leadership and contributions in intelligent simulation and industrial metaverse solutions.

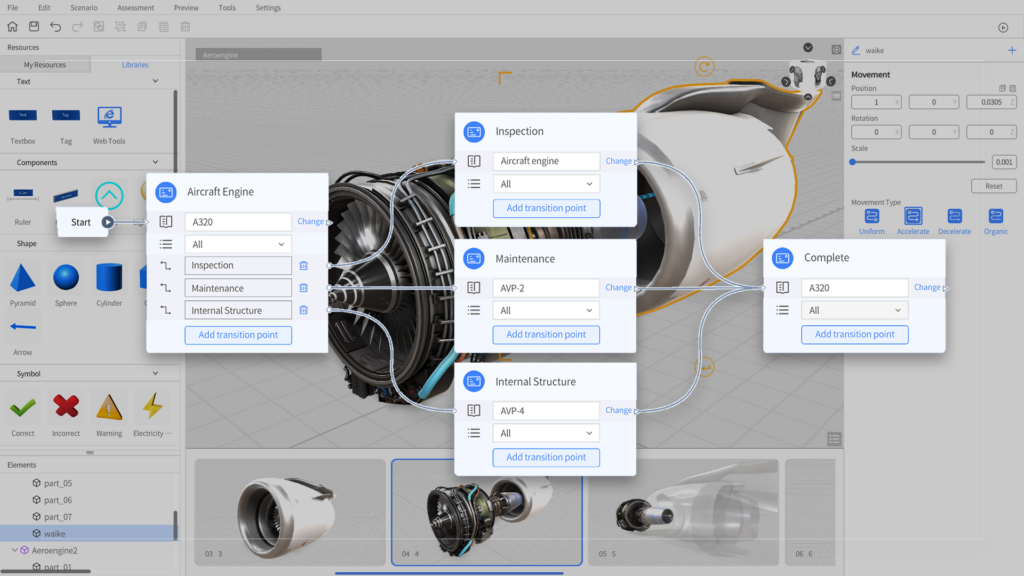

DataMesh Director Gets a Major Upgrade: The New “Storyline”

The latest version of DataMesh Director introduces the new trial feature “Storyline”, which is especially useful for managing scenarios for large exhibition projects and complex operational guidance. Additionally, the new version also brings optimizations in model preprocessing and viewer experience.

Collaboration Between JTC & DataMesh: Advancing Construction Efficiency with Digital Twin and Mixed Reality

By integrating BIM data with MR technology, the platform empowers frontline workers to visualise and understand complex construction tasks in both virtual and real-world spaces, significantly improving efficiency on job sites.

DataMesh Simulator Introduces New Training Environments for Crawler Excavator Operations

Introducing new courseware for crawler excavator training, the innovative training environment features realistic simulations, engaging visuals, and real-time feedback, streamlining the learning process and revolutionizing excavator training while reducing costs.

DataMesh Joins NVIDIA Inception, Empowering Affordable Enterprise Digital Twins Creation

DataMesh FactVerse + NVIDIA Omniverse, help enterprises create affordable digital twins of equipment, processes, and facilities, thereby facilitating significant business growth.