Manufacturing Optimization

Equipment Performance Tracking

DataMesh FactVerse enables real-time tracking of equipment performance by integrating IoT data, digital twins, and advanced analytics. This allows businesses to monitor key metrics, identify inefficiencies, and predict potential issues before they escalate. By providing actionable insights, FactVerse helps optimize equipment utilization, improve reliability, and reduce operational costs.

Product & Services

FactVerse Data Fusion Services

DataMesh FactVerse DFS integrates data streams from diverse sources—such as equipment sensors, operational logs, and enterprise systems—into a unified platform for machine learning analysis. Users can route this data to various ML models for advanced analytics, enabling predictive insights and automated issue detection. Additionally, DFS supports the creation of custom alert rules, helping organizations track future equipment performance and identify potential problems in real time, thus reducing downtime and improving operational efficiency.

FactVerse AI

FactVerse AI transforms enterprise data into actionable insights with tools like multi-language translation, synthetic data, and intelligent search. It enhances digital twin operations, streamlines workflows, and empowers smarter decisions, driving efficiency and reducing costs in digital transformation.

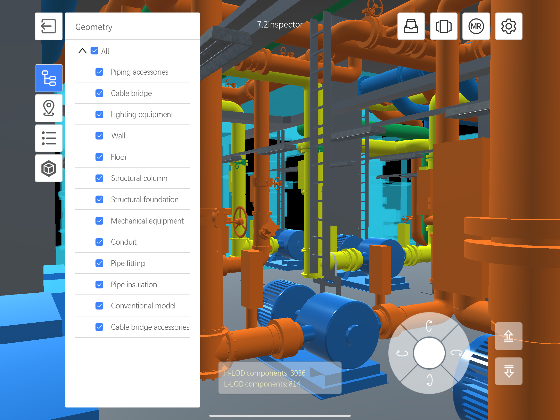

DataMesh Inspector

DataMesh Inspector with AI transforms industrial maintenance with digital twins and AI insights, enabling real-time AR inspections, anomaly detection, and predictive analytics. It enhances accuracy, reduces downtime, and empowers workers to handle complex tasks confidently.

Customer Cases

A Leading Aircraft MRO Provider

A leading aircraft MRO provider for major airlines utilizes DataMesh DFS to streamline data processing and monitor equipment performance. By integrating real-time sensor data and historical maintenance records, they gain valuable insights into aircraft health and operational efficiency. Predictive maintenance capabilities allow the provider to anticipate issues, reducing downtime and optimizing maintenance schedules. This implementation has resulted in enhanced reliability, lower maintenance costs, and improved productivity, ensuring the airline's fleet remains safe and efficient.

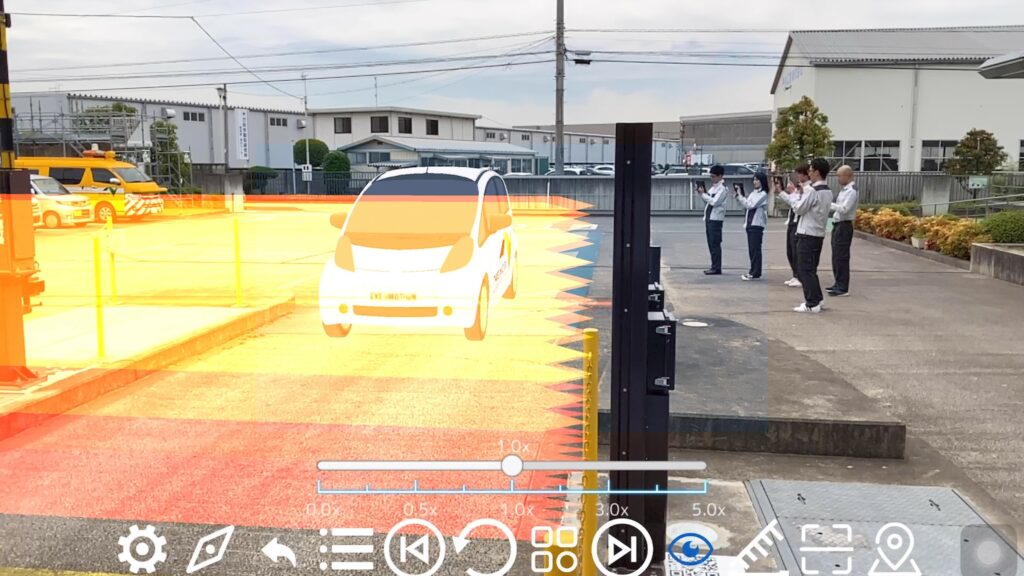

NEXCO East Japan

NEXCO East Engineering, challenged by aging highway infrastructure and a shortage of skilled technicians, enhanced training at its Technical Training Center (TTC) through a collaboration with DataMesh. By developing MR (Mixed Reality) and digital twin–based content for ETC systems and tunnel emergency equipment, they enabled trainees to visualize otherwise invisible processes—like infrared signals or internal water flow—in 3D overlays on actual devices. This immersive approach significantly improved knowledge retention and training consistency, while laying a foundation for expanded ICT-driven initiatives such as remote maintenance.