DataMesh FactVerse

Industrial Metaverse Platform for Frontline Workers

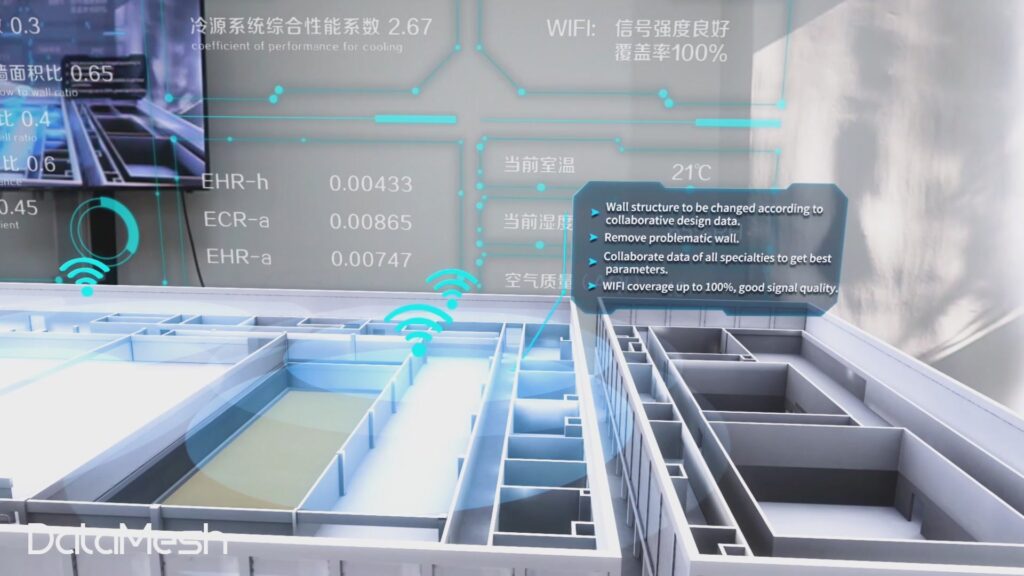

FactVerse combines digital twins, enterprise knowledge graphs, and mixed reality to enable companies to simulate, visualize, and analyze real-world operations in a virtual space. This platform improves decision-making efficiency, optimizes workflows, and opens up new possibilities for training and collaboration for frontline staff by providing an immersive interactive experience.

The platform is equipped with multiple types of CAD/BIM data import conversion and optimization, document and activity management, IoT platform data aggregation and management, intelligent search and recommendation, and real-time cross-region distribution, making it simple and easy to build digital twin applications.

Addressing data silos

FactVerse connects 3D data and IoT data, allowing users to quickly build digital twins, connect traditional corporate information silos in a more intuitive way, and tap into their potential and business value.

Digitization of workflow

Difficult to digitize existing processes?FactVerse Designer supports drag-and-drop layout, digital twin templates, and behavioral tree editing, allowing business users and developers to quickly edit and modify digital twin associations, expected behaviors, and data bindings, reducing development complexity by 60-80%.

Understanding Unstructured Data

In addition to supporting fast docking and intelligent retrieval of traditional enterprise data, FactVerse supports a wide range of CAD/BIM data, providing users with a number of services such as import, lightweighting, acceleration, and metadata extraction. It also supports access to IoT platforms, allowing 3D data to be combined with real-time data.

From static mapping to simulation prediction

FactVerse's hybrid deployment component, Data Fusion Service (DFS), not only supports data mapping from IoT platforms, enterprise ERP, MES, reporting systems, SCADA, and various types of time-series databases, but also supports secondary development based on digital twin environments, allowing process simulation and predictive maintenance applications to be quickly interfaced with end-users.

Connecting Digital Twin Data and Apps

Data Import

- Mainstream structured and unstructured data support

- Automatic incremental content extraction

- Existing CAD, BIM resource utilization

- Cloud-based automatic/semi-automatic optimization

- Mobile Ready

- Metadata Mapping

Data Mapping

- Maps device status data, report data, kanban data, etc. through Digital Twin interface.

- Quickly interface with SCADA, MES, ERP, various IoT platforms, and timing databases through Data Fusion Service (DFS).

Simulation

- FactVerse SDK

- Business logic, simulation plug-in development

- Invoke digital twin and business resources in scenarios

- Rapidly build professional scenarios for predictive maintenance, operation optimization, etc.

Distribution

- DataMesh One, Inspector, Checklist, Simulator, Web or homegrown applications

- Support for all types of displays, XR glasses, handheld devices

- Invoke cloud-based digital twin scenarios across geographies

- Improve the efficiency of frontline staff

Empower Digital Twins

Reuse Digital Twin Content

FactVerse can import common industrial CAD and architectural BIM data for lightweighting and optimization acceleration. By abstracting and describing the digital twin content, key information of complex scenes and equipment can be retrieved at any time for secondary development, and used to build all kinds of visualization, process simulation, analysis and prediction applications.

Connect Your IoT Business

The FactVerse industrial meta-universe platform can quickly connect to all kinds of ERP, MES, SCADA, time-series databases, and IoT platform systems through DFS to build data connection description files to bind with 3D content. From reports and kanban data, to vehicle movement trajectories, to the movement angle data of each joint of a robotic arm, DataMesh Digital Twin Cloud supports millions of device data connections, making it possible to build a digital world that is mapped in real time to the physical world.

Spatial Computing

FactVerse’s spatial anchor positioning information can be combined with the SLAM capability of various XR devices to map the content in the digital world to the corresponding location in the real world, so that the digital twin content can be directly combined with the on-site reality, whether it’s the perspective of the hidden works, rapid confirmation of the construction procedures and methods, or the rapid teaching of the structure of the equipment, the combination of the real and the virtual can quickly improve the efficiency of the application and enhance the experience.

Flexible Deployment Options

The FactVerse platform, as a standard product, can be used to rapidly deploy applications in the enterprise, supporting purely public SaaS model purchases (DataMesh Director, Checklist, Inspector and other products) in mainland China, Japan and Singapore. To support enterprise sensitive data with high confidentiality level, users can choose DCSA all-in-one server for private deployment.

The FactVerse platform also supports a hybrid deployment approach – e.g., DFS to acquire data in a private environment while utilizing a public cloud platform for authoring and distribution. Users can also migrate data between different private platforms and public cloud regions in parallel, supporting frontline staff in real-world use while meeting confidentiality requirements in different environments.

The digital twin template layout and behavioral tree design provided by DataMesh FactVerse dramatically simplifies data platform issues in digital twin factory projects. Multiple developers can use the same interface to access the standardized layout and logical data to develop different business applications without worrying about the underlying data connectivity issues. The cost of modifying and adjusting layouts to follow business changes is also dramatically reduced.

Digital Factory Project

Project Manager

FAQ

FactVerse platform connects enterprise traditional data and 3D resources (including CAD, BIM-type data and 3D resources generated by other means) to rapidly build programmable digital twin entities and scenarios, and at the same time supports millions of data connections and distribution and collaboration.

FactVerse provides multiple types of traditional enterprise data import, CAD/BIM data import and lightweighting, model acceleration, intelligent search recommendation, real-time data binding, collaborative activity creation and management, and other processing capabilities. Support secondary development.

Based on the FactVerse industrial metaverse platform, enterprises can quickly build multiple types of scenarios such as operation process simulation, construction planning and supervision, maintenance and inspection, training and guidance, and after-sales support.

FactVerse supports parallel migration of data between different deployment types, allowing users to export packaged digital twin content packages and upload them to the appropriate public cloud or DCSA private cloud environment. In hybrid cloud scenarios, content developers usually edit and develop digital twin scenarios in private environments, and then synchronize them to the public cloud for release to multiple users, and data can also be migrated between different regions of the public cloud in this way. The public environment is currently operated in three regions: mainland China, Japan and Singapore.

Public clouds can be turned up within 24 hours and private cloud systems can usually be deployed in less than 1 week. Actual application development and deployment usually takes less than three months.

Please contact us to further communicate detailed program requirements.