Manufacturing Optimization

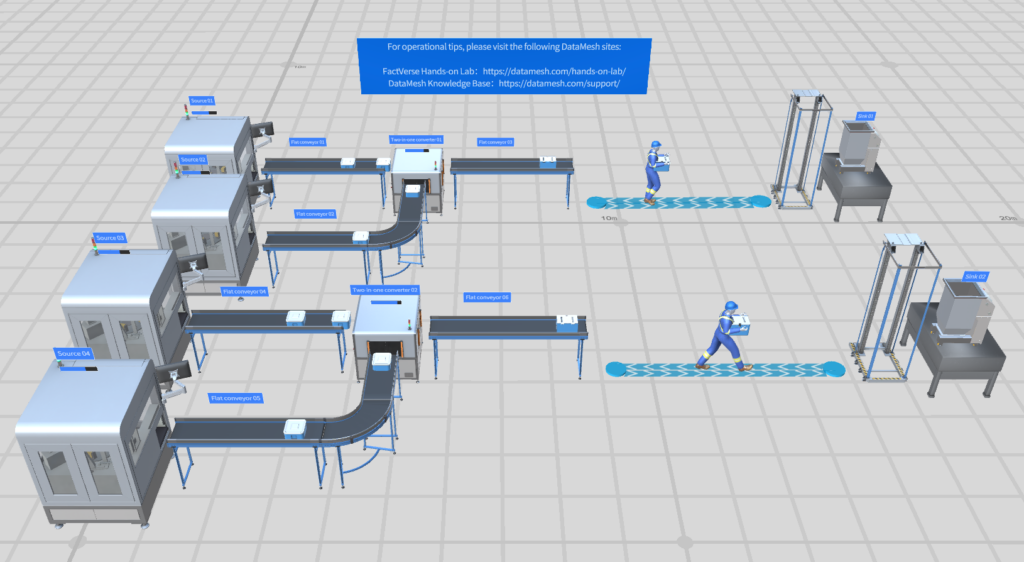

Warehouse Process Simulation

FactVerse empowers businesses with advanced warehouse process simulation, enabling the creation of digital twins for warehouses to optimize logistics, layout, and workflows. Businesses can identify bottlenecks, reduce costs, and enhance productivity by simulating operations like material flow, storage utilization, and equipment efficiency. With real-time data integration and scenario testing, FactVerse helps streamline warehouse operations, ensuring maximum efficiency and scalability.

Product & Services

FactVerse Designer

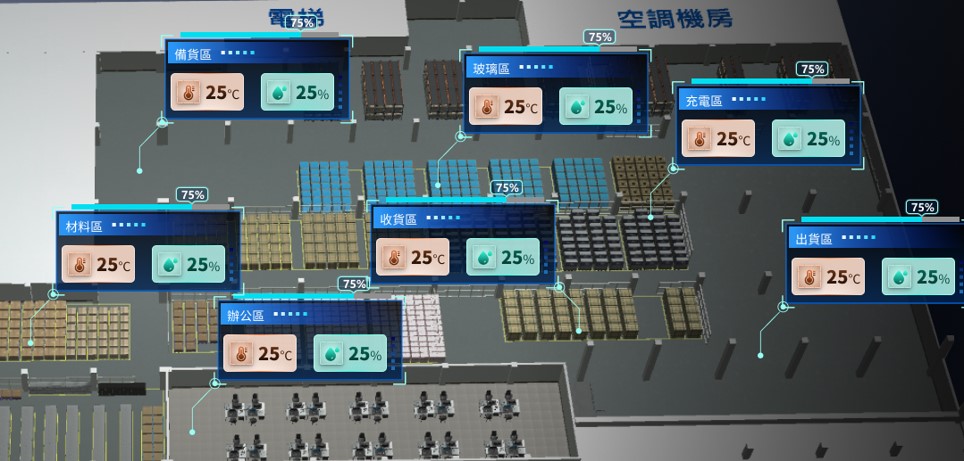

FactVerse Designer allows users to swiftly build digital twin layouts and construct behavior trees, linking real-world data to specific entities within the virtual environment. By combining spatial modeling with live data integration, FactVerse Designer produces accurate, up-to-date representations of physical operations—generating reliable ground truth for simulations, analytics, and AI model training. This streamlined approach empowers businesses to refine processes and optimize performance in a highly intuitive, data-driven manner.

Data Fusion Services

DataMesh FactVerse’s Data Fusion Services (DFS) unifies real-world data from IoT sensors, enterprise systems, and automation platforms, linking physical environments with digital twins in real time. By continuously ingesting and processing diverse data streams, DFS keeps workflows, simulations, and analytics accurate and up to date, enabling informed decision-making and optimized operations in rapidly changing industrial settings.

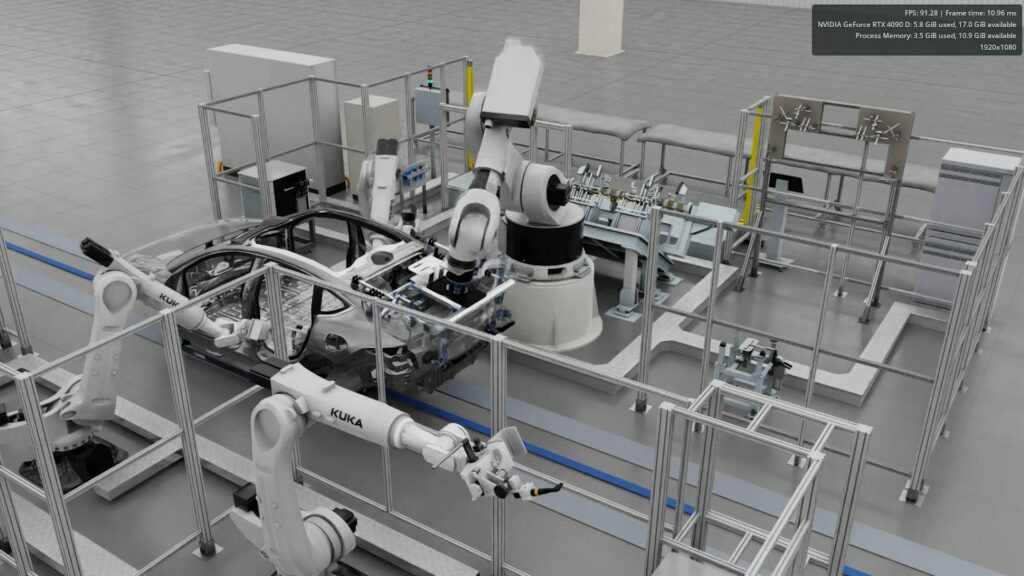

DataMesh FactVerse Connector for NVIDIA Omniverse

The FactVerse Connector integrates DataMesh’s real-time data fusion and digital twins with Omniverse’s advanced simulation and rendering, enabling high-fidelity 3D environments, AI training with ground truth data, and optimized workflows. This collaboration empowers businesses with enhanced design, operations, and training capabilities.

Customer Cases

AUO

AUO implemented a digital twin platform within two weeks to optimize manufacturing operations. Utilizing FactVerse Designer for 3D layout design and real-time monitoring, integrating IoT, ERP, and MES data through DFS, and utilizing DataMesh Director & Checklist for 3D operations manuals and inspection processes, the project achieved reduced equipment downtime, significantly improved personnel efficiency by shifting to a "data finding people" approach and visualization of warehouse operations and inventory, and developed new digital capabilities for customers.