Industrial Digital Twin Solutions

Real-Time Monitoring and Control

DataMesh FactVerse provides real-time monitoring and control by integrating digital twins, IoT data, and operational workflows into a unified platform. This allows businesses to track performance, detect anomalies, and respond to issues instantly. With live data visualization and actionable insights, FactVerse enhances operational efficiency, reduces downtime, and ensures seamless management of complex systems.

Product & Services

Data Fusion Services

DataMesh’s Data Fusion Services connects and consolidates data from Facility BMS systems, IoT devices, and digital twins into a unified platform. This enables real-time data mapping, cross-system insights, and seamless integration of building operations. By breaking down data silos, it improves resource management, optimizes energy efficiency, and enhances facility performance, empowering smarter decision-making and sustainable operations.

FactVerse AI

FactVerse AI transforms enterprise data into actionable insights with tools like multi-language translation, synthetic data, and intelligent search. It enhances digital twin operations, streamlines workflows, and empowers smarter decisions, driving efficiency and reducing costs in digital transformation.

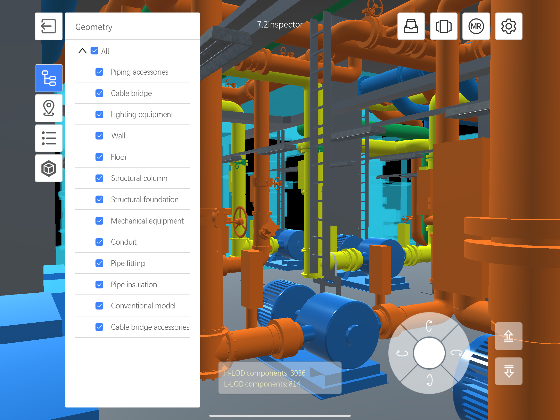

DataMesh Inspector

DataMesh Inspector with AI transforms industrial maintenance with digital twins and AI insights, enabling real-time AR inspections, anomaly detection, and predictive analytics. It enhances accuracy, reduces downtime, and empowers workers to handle complex tasks confidently.

Customer Cases

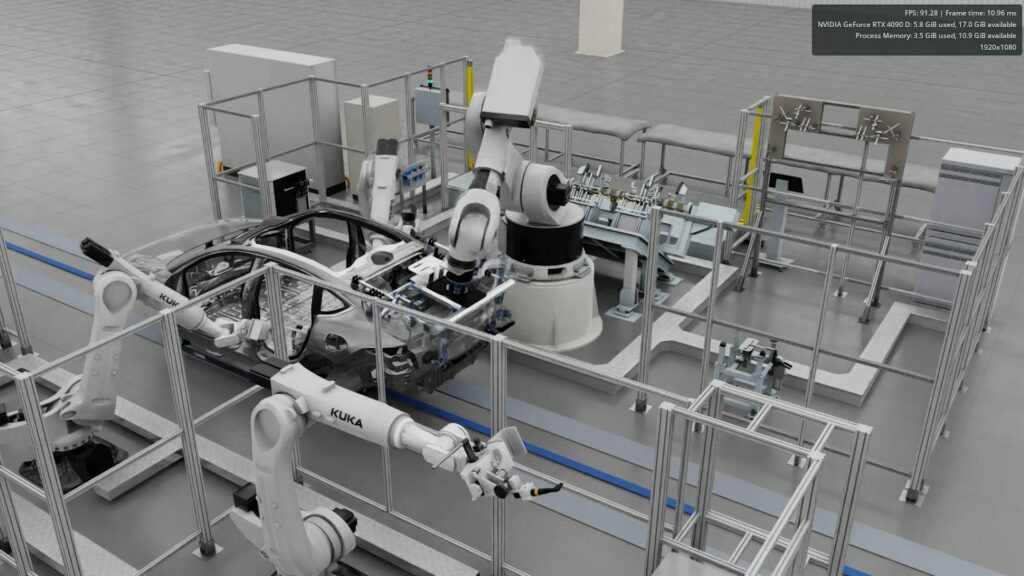

NIO

NIO partnered with DataMesh to implement a digital twin platform for vehicle assembly, transforming production management through real-time monitoring, accurate layout simulation, and seamless data integration from AGVs and RFID systems. Using FactVerse’s no-code approach and robust data fusion engine (DFS), engineers quickly created digital replicas of equipment and workflows, reducing downtime and improving efficiency across the entire production line. This success sets a new standard for digital innovation in manufacturing, laying a solid foundation for NIO’s future growth.

A Leading Truck Manufacturer

A top commercial vehicle maker used DataMesh FactVerse to establish a digital twin for its truck assembly operations, enabling real-time equipment monitoring and workflow management. Engineers swiftly created immersive 3D models of facilities and machinery, testing layout scenarios without interrupting production. By integrating FactVerse’s data fusion services with live sensor data, the company gained instant equipment insights, supported predictive maintenance, and improved workflow coordination—significantly reducing costs while elevating smart factory standards in the commercial vehicle industry.

A Leading Advanced Manufacturing Customer

The customer leveraged DataMesh FactVerse, Data Fusion Services, and DataMesh Checklist to enhance operational efficiency across their production lines. By integrating real-time data, digital twins, and operational workflows into a unified platform, they enabled precise monitoring, seamless collaboration, and actionable insights. DataMesh Checklist provided step-by-step guidance for frontline workers, ensuring accurate task execution and minimizing errors. This system of systems approach streamlined processes, reduced downtime, optimized energy usage, and improved productivity while supporting the customer’s sustainability goals.

A Leading Resort Operator

The customer used DataMesh FactVerse and Data Fusion Services to integrate Facility BMS systems, IoT devices, and digital twins into a unified platform. This enabled real-time monitoring, optimized energy use, improved resource management, and enhanced operational efficiency. By streamlining operations and meeting sustainability goals, the operator delivered a smarter, more eco-friendly experience for guests and staff.