DataMesh Supports Faurecia and EVE Energy Toward WEF Lighthouse Recognition

DataMesh supported the digital transformation of two newly recognized WEF Lighthouses. At Faurecia, VR-based training enabled scalable, standardized workforce development. At EVE Energy, a digital twin platform delivered unified operational visibility, process simulation, and energy optimization, accelerating real-world intelligent manufacturing outcomes.

DataMesh and Yokogawa Launch an AI-Driven Predictive Maintenance Solution for Industrial Facilities

DataMesh and Yokogawa have partnered to deliver an AI-powered predictive maintenance solution that integrates industrial sensing, AI analytics, and digital twins. The solution enables earlier risk detection, reduces false alarms, and helps operators move from reactive maintenance to proactive prevention.

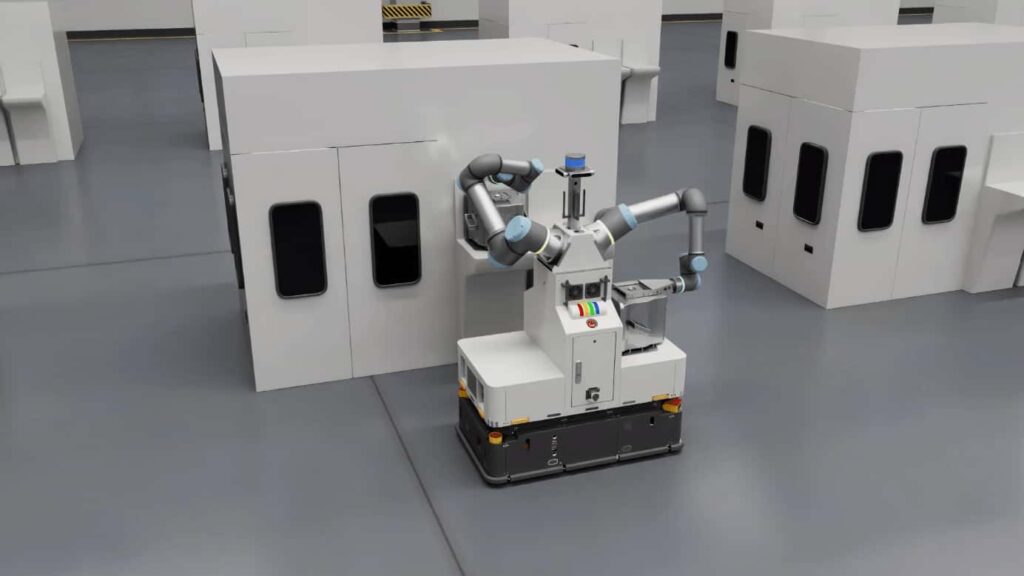

DataMesh Launches Embodied AI Data Product Solution — DataMesh Robotics

Built on an “Executable Industrial Digital Twin,” the solution provides dynamic business simulation, industrial scene modeling, physics and sensor simulation, photorealistic synthetic data generation, and automated ground-truth labeling—plus practical methods for defining industrial task objectives and reward signals. It integrates with NVIDIA Isaac Sim / Omniverse and is piloted by enterprises for robotics deployment in production, inspection, and operations.

DataMesh Joins the NVIDIA Omniverse Partner Council JAPAN

The expanded collaboration unlocks new possibilities for industrial digital twins, physically accurate simulation, and embodied AI—helping manufacturers design, validate, and optimize production with greater speed, confidence, and realism.

Jebsee Accelerates Production Line Automation Planning with DataMesh FactVerse, Cutting Risk and Boosting Communication

Jebsee, a leading Taiwanese manufacturer of automotive antennas and communication modules, used DataMesh FactVerse to simulate production line automation upgrades and reduce planning risk. The platform improved communication, delivered data-driven insights, and helped boost throughput while building a reusable digital foundation for future growth.

Gyro × DataMesh: Making Intralogistics Automation Solutions Easier to Understand, Validate, and Implement with Digital Twins

Gyro, a leading AMR and smart intralogistics provider in Taiwan, partnered with DataMesh to deliver a digital-twin-powered simulation approach—built on FactVerse and NVIDIA Omniverse—that helps customers see automation value upfront and make decisions faster.

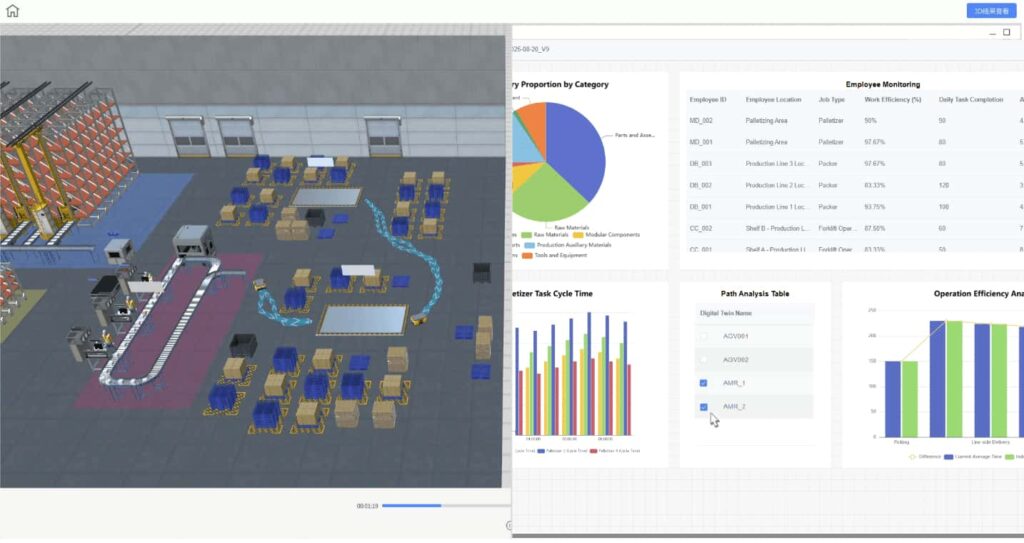

DataMesh FactVerse September Update: Smarter Decisions Powered by Integrated Simulation and Data Analytics

A major upgrade to the Data Fusion Service (DFS) now brings deep integration with FactVerse Designer’s simulation capabilities. Enterprises can not only visualize operations in 3D but also turn simulations into interactive dashboards and insights—accelerating smarter, faster decision-making.

DataMesh Recognized as a Tech Innovator in 2025 Gartner® Emerging Tech Report on Intelligent Simulation

DataMesh sees this recognition as a reflection of its ongoing commitment to delivering a practical, user-friendly simulation platform that drives real business value — helping enterprises to improve efficiency, reduce downtime, and optimize decision-making in real time.

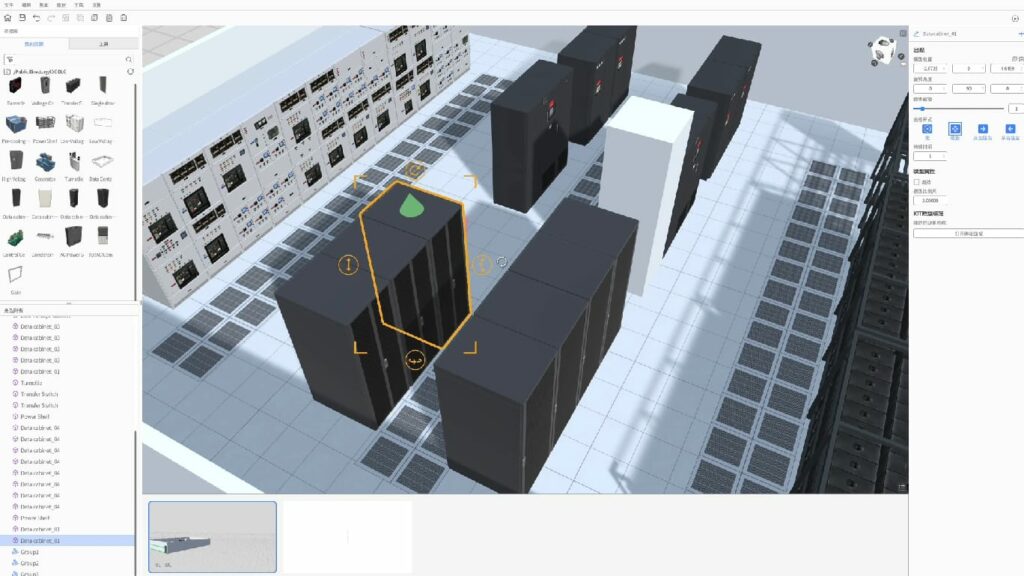

Introducing the new IDC DLC: Build Your Digital Twin Data Center with Ease

The new IDC DLC offers a rich library of standard 3D models commonly used in the IDC industry. Combined with the FactVerse platform’s powerful data tools, it supports key use cases like energy monitoring, temperature & humidity control, power optimization, and anomaly detection—ensuring safe and efficient operations.

DataMesh Showcases Simulation Digital Twins Powered by DataMesh FactVerse and NVIDIA Omniverse at GTC 2025

FactVerse to further support enterprises to build high-quality simulation digital twins and AI solutions with NVIDIA Omniverse technologies, and introduce a new NVIDIA Omniverse extension, to seamlessly connect FactVerse to applications developed on Omniverse.