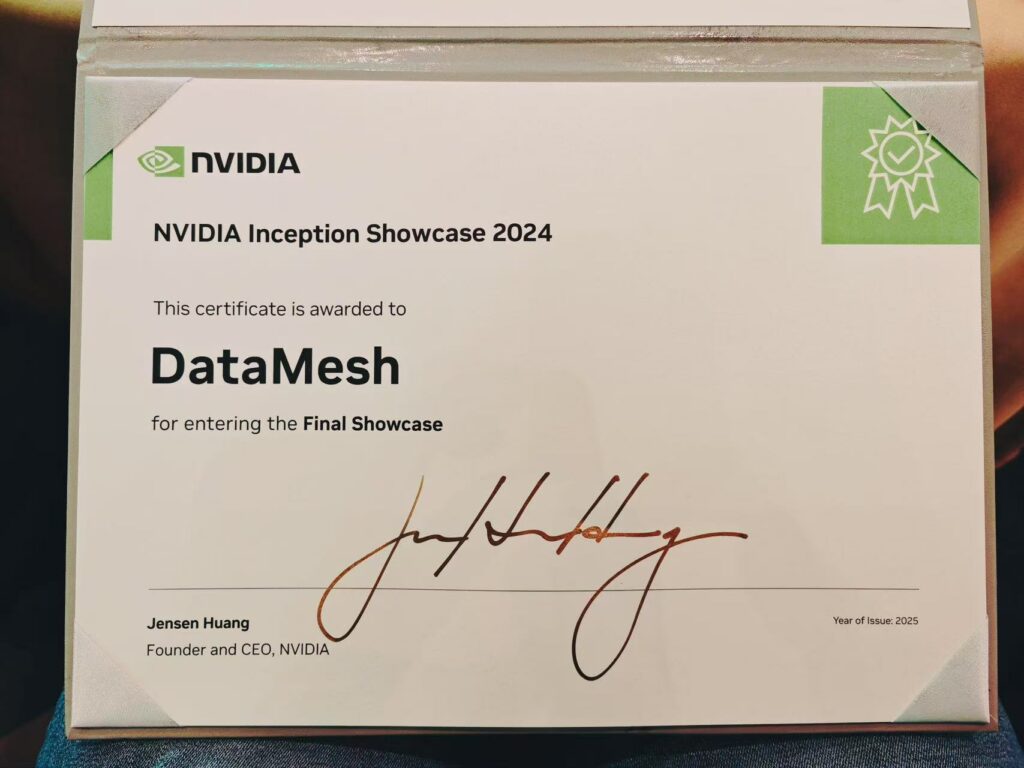

On January 19, DataMesh CTO Hao Wu attended NVIDIA Appreciation Awards Ceremony, where he represented DataMesh in the NVIDIA Inception Final Showcase Award. DataMesh joined NVIDIA Inception Program in 2024 and was recognized as one of the Top 10 Finalists of the 2024 NVIDIA Inception Showcase.

DataMesh focuses on the development and services of Simulation Digital Twin platforms. The company leverages cutting-edge digital twin technology, spatial computing, and AI to help businesses revolutionize their workflows and empower frontline workers.

DataMesh’s FactVerse platform is an in-house developed digital twin solution that allows companies to create digital twins at a low cost, optimizing production workflows and reducing operational expenses through business process monitoring and simulation.

DataMesh is now working closely with NVIDIA to integrate the strengths of FactVerse and NVIDIA Omniverse, making the deployment of digital twins more efficient, sustainable, and user-friendly. This collaboration aims to empower key stages of manufacturing, ultimately enhancing operational efficiency.

Key Challenges in the Manufacturing Industry

- Labor Shortages and Skills Gaps: Changing demographics have led to a shrinking workforce, and the transfer of knowledge among frontline workers has become increasingly difficult. High training costs for skilled workers are adding to the pressure. As companies expand globally, language and cultural differences also present barriers to effective training.

- Operational Inefficiencies: The complexity of modern production processes demands higher operational capabilities. Yet many businesses still struggle with data silos, preventing them from integrating and utilizing production data effectively. Without consistent and reliable data, achieving data-driven optimization remains a significant challenge.

The Challenges of Digital Twin Deployment

To boost productivity, digital twin technology is increasingly being adopted in industrial manufacturing. However, its deployment is not without hurdles:

- High Development Costs for Digital Twin Scenarios: Traditional development of digital twin scenarios often involves high technical and labor costs, making it difficult to quickly adapt to changing business requirements.

- Data Fusion and Mapping Complexities: Production data comes from various sources, often stored in different formats. Effectively integrating this data and mapping it to 3D models for seamless operation is a complex task. Additionally, achieving real-time, physically accurate simulations requires significant computational resources.

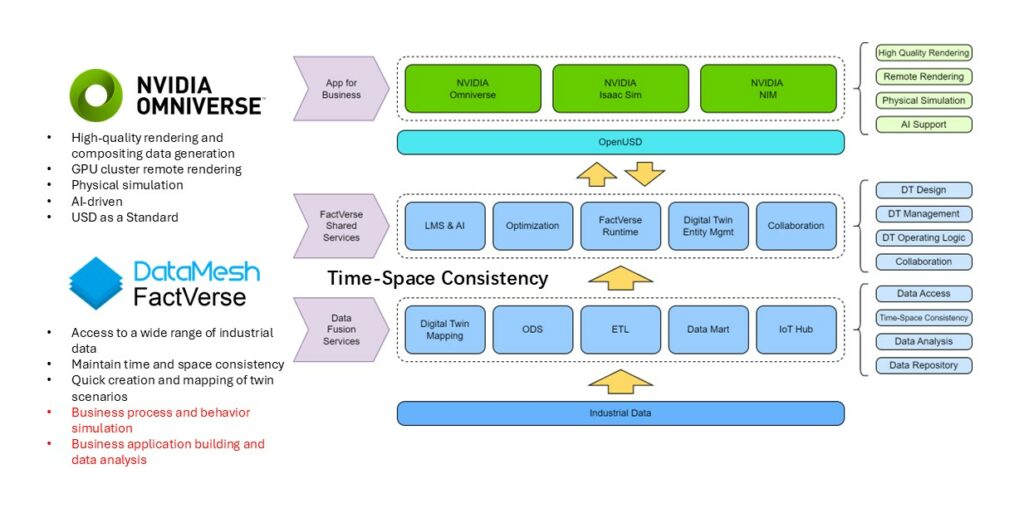

DataMesh FactVerse + NVIDIA Omniverse™: A High-Quality, Spatiotemporally Consistent Simulation Digital Twin and AI Business Platform

By deeply integrating NVIDIA Omniverse with FactVerse, DataMesh has created a high-quality digital twin solution for industrial applications. This powerful combination allows manufacturing businesses to quickly build spatiotemporally consistent digital twin platforms, driving improvements in business operations and supporting growth on the frontline.

FactVerse and Omniverse each play a pivotal role in this solution. FactVerse focuses on building digital twin scenarios and simulation logic, as well as data integration and processing, which is essential for accurate virtual-physical mapping and data-driven decision-making. Omniverse, in turn, enhances the rendering quality of digital twin scenarios, utilizes NVIDIA Isaac™ for precise industrial simulations, and strengthens AI capabilities through NVIDIA NIM™.

Looking ahead, connecting with NVIDIA Cosmos™ World Foundation Models will further boost the simulation and generative capabilities of industrial metaverses, providing robust platform-level support for AI-driven production optimization and AI training for industrial robots.

FactVerse: Building the Foundation of Digital Twins

- Multisource Data Integration: FactVerse’s Data Fusion Service (DFS) can seamlessly integrate data from various production systems, ensuring spatiotemporal consistency and providing a solid data foundation for business simulations and optimization.

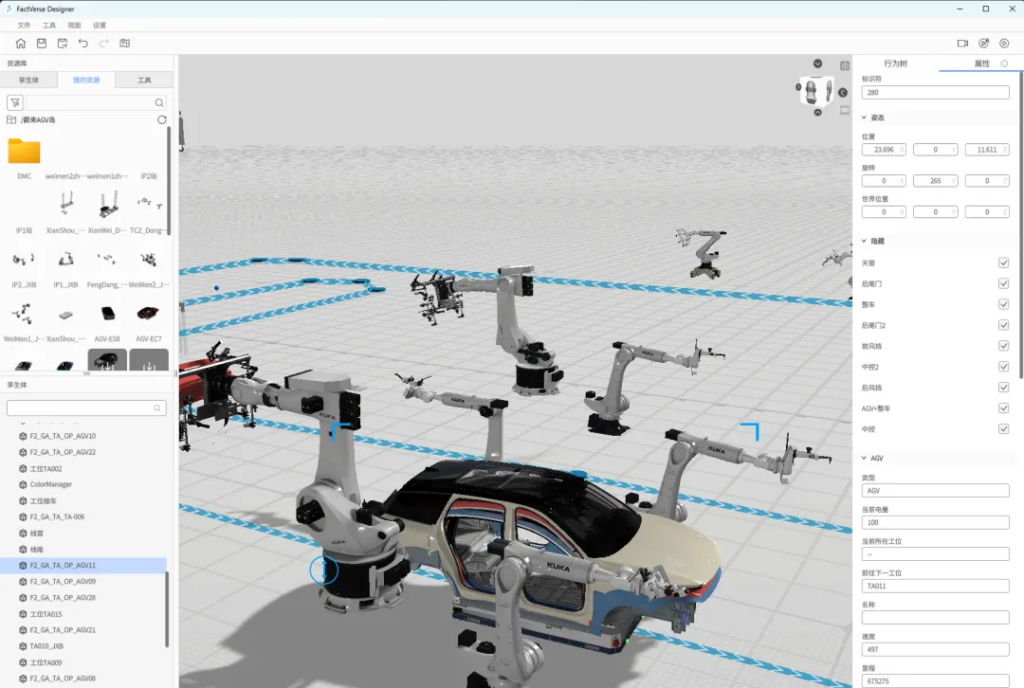

- No-Code Digital Twin Creation: With FactVerse Designer, a no-code platform, frontline workers can easily import 3D models, create digital twin scenarios, and define operational logic without any coding. This simplifies the process and reduces development time.

- Cloud-Based Simulation and Collaboration: FactVerse offers a cloud-based environment for digital twin simulations, enabling collaborative work among multiple users.

NVIDIA Omniverse and NVIDIA RTX™ GPUs: Accelerating AI and Physical Simulations

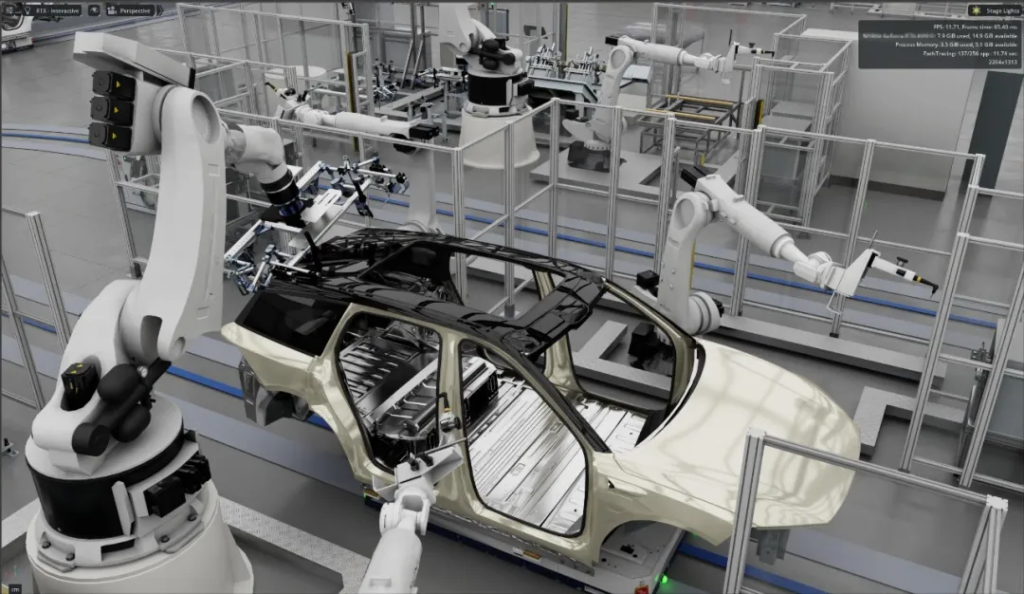

- High-Quality Rendering: By using OpenUSD as the intermediary, FactVerse sends digital twin data to NVIDIA Omniverse, where it is rendered in high quality. Omniverse’s remote rendering capabilities also enable users to view large 3D scenes in a browser, enhancing collaboration and interaction.

- Enhanced Physical Simulation: NVIDIA Isaac handles industrial-grade physical simulations, feeding results back into FactVerse for more realistic digital twin operations.

- AI-Powered Optimization: With NVIDIA NIM, businesses can deploy large and small AI models, combining them with company knowledge bases and digital twin data. This empowers frontline workers with AI-driven tools, like smart search and guidance, to increase productivity.

- GPU Acceleration: Thanks to the advanced capabilities of the NVIDIA RTX™ 5880 Ada GPUs, Omniverse delivers faster, higher-quality rendering, supporting large-scale simulations of industrial assets, processes and environments, and helping businesses build physically accurate digital twins and virtual simulations.

Unleashing the Potential of Digital Twins to Empower the Future of Manufacturing

By combining NVIDIA Omniverse, RTX, and the efficient integration of DataMesh FactVerse, this solution offers manufacturing enterprises a seamless virtual-physical fusion for digital transformation. It enables businesses to create digital twins of equipment, processes, and facilities at a low cost, helping them boost efficiency and create long-term value.

Simple, Efficient Deployment with Long-Term Business Value

From a technical perspective, this solution lowers the barrier to deploying digital twins and shortens development time. FactVerse addresses the challenges of building digital twin scenarios and data fusion, while its no-code designer simplifies the process. Digital twin scenarios and models are reusable and adaptable to changing business needs. Over time, this flexibility reduces development costs, increases ROI, and fosters a positive feedback loop.

Moreover, the user experience is greatly enhanced. FactVerse’s digital twins are not dependent on a specific rendering engine, allowing for seamless integration with Omniverse. High-quality rendering powered by Omniverse and RTX GPUs offers users more realistic visuals and a more natural, intuitive interactive experience.

From a business perspective, a spatiotemporally consistent digital twin platform enables data-driven decision-making and integrates AI capabilities into core business operations. Through simulating real-world processes and applying AI, this platform delivers significant value to manufacturing enterprises, particularly in areas such as production, equipment maintenance, and employee training.

Optimizing Manufacturing Processes

With the spatiotemporally consistent digital twin platform built on FactVerse and Omniverse, enterprises can achieve more intuitive production monitoring and better business simulations, resulting in optimized production workflows and improved operational efficiency.

During the production line planning stage, businesses can simulate layouts based on production schedules and process combinations—such as equipment placement and AGV routes—helping them identify the best configurations and avoid costly adjustments in the real world.

During production, the 1:1 digital twin and real-time data mapping allow frontline workers to quickly identify bottlenecks, using time and space data to rapidly pinpoint problems. Additionally, by simulating production workflows, companies can validate production plans, optimize schedules, and improve efficiency.

FactVerse also offers a range of out-of-the-box tools, including AR/VR-based solutions, to help frontline workers better understand equipment operations and performance, leading to more efficient training and smarter equipment maintenance.

In the future, as digital twins become more deeply integrated with real-world business data, AI applications will continue to evolve. For example, using digital twin data for AI training will provide more robust training environments for advanced technologies like autonomous vehicles and robotic arms, further enhancing production optimization.

DataMesh CTO Wu Hao remarked, “Through deep integration with NVIDIA Omniverse, we can more efficiently create digital twins. DataMesh and NVIDIA are committed to helping more enterprises leverage digital twins, XR, and AI technologies to enhance frontline worker capabilities and improve organizational efficiency.”

*Images or videos related to NVIDIA products (full or partial) are copyrighted by NVIDIA Corporation.