DataMesh has partnered with Yokogawa to introduce a joint AI-driven predictive maintenance solution, redefining how industrial facilities monitor, understand, and manage critical equipment.

The solution is designed to address long-standing challenges in industrial operations and maintenance, including limited early fault detection, overreliance on manual experience, and low-confidence alarms.

Targeting critical rotating equipment such as pumps, compressors, and motors, the solution integrates industrial-grade sensing hardware, AI-powered data exploration, and digital twin technologies. By transforming raw sensor data into interpretable, analyzable, and predictive insights, the solution enables industrial operators to identify potential risks well before failures occur and take proactive actions ahead of unplanned downtime.

Why Traditional Monitoring Falls Short

In process industries, energy, power generation, and advanced manufacturing, equipment failures rarely occur without warning. Degradation often begins weeks in advance, reflected in subtle changes in vibration, temperature, and other signals.

Despite widespread sensor deployment, many facilities still rely on static thresholds and isolated measurements. This results in frequent false alarms, delayed responses, and large volumes of data that fail to translate into actionable insight.

The challenge is not data availability, but data understanding. Sensor data is often disconnected from operational context, business systems, and spatial information—making it difficult to distinguish meaningful risk from background noise.

A New Approach: Sensors, AI, and Digital Twins Working Together

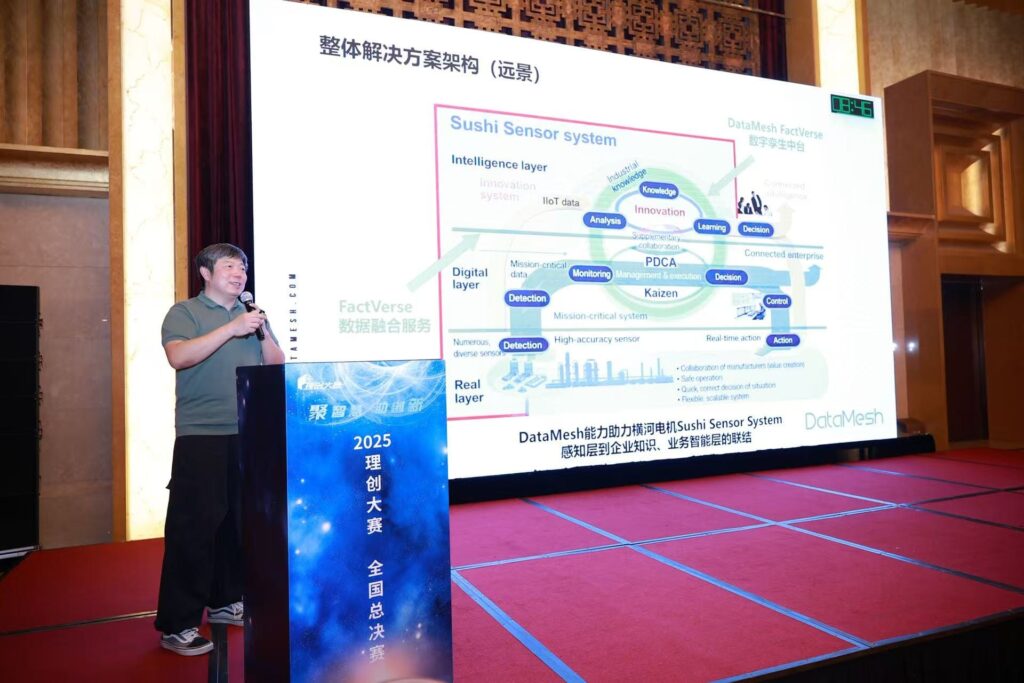

DataMesh and Yokogawa have developed an end-to-end intelligent maintenance solution that unifies sensor data, equipment information, and operational context into a single analytical framework.

Through AI-driven analysis and digital twin visualization, equipment conditions are continuously assessed, trends are evaluated dynamically, and potential risks are identified well before failures occur. Maintenance strategies shift from reactive responses to predictive and preventive action.

Yokogawa: Reliable Industrial Sensing at the Core

Yokogawa provides the trusted sensing foundation that ensures data accuracy and engineering relevance:

- Industrial-grade vibration, temperature, and fiber-optic sensors designed for harsh and complex operating environments

- Deep expertise in process industries, ensuring sensor data reflects real equipment behavior under real operating conditions

- Proven field deployments across a wide range of industrial scenarios, delivering stable and reliable data at scale

DataMesh: Turning Industrial Data into Actionable Intelligence

On top of this sensing foundation, DataMesh transforms raw data into insights that operators can understand and act upon:

- Multi-source data integration

Sensor data is unified with DCS, MES, enterprise systems, and spatial data—aligning time, assets, and operational context into a consistent data foundation. - Digital twin–based visualization

Equipment conditions and operating environments are represented in real time, enabling faster understanding and more confident decision-making. - Visual, multi-dimensional analysis

Engineers can explore data using an intuitive, drag-and-drop analytics canvas with built-in analytical methods. - AI-powered data exploration

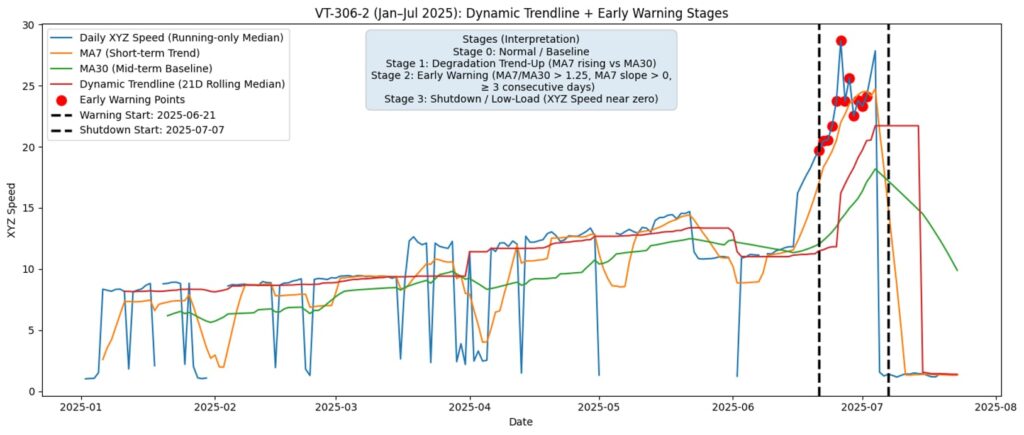

AI agents automatically identify relevant operational data segments from historical data, distinguishing between different operating states, and evaluate evolving trends to determine whether equipment conditions are deteriorating.

Thresholds and baselines adapt dynamically as data evolves, significantly reducing false alarms while improving anomaly detection reliability.

Together, these capabilities enable earlier, more trustworthy identification of emerging risks—shifting maintenance from corrective action to proactive prevention.

From Predictive Maintenance to Intelligent Facility Management

In proof-of-concept deployments using real industrial equipment data, the solution has demonstrated the ability to identify potential risk windows 10–14 days earlier than traditional methods. This provides valuable time for planned maintenance, load optimization, and energy efficiency improvements, while reducing losses from unplanned downtime.

Over time, insights gained through data exploration can be formalized into reusable operational rules and extended into broader intelligent facility management, including asset health monitoring, alarm-to-work-order automation, maintenance resource optimization, and AI- and AR-assisted operations.

Looking Ahead

DataMesh and Yokogawa will continue to deepen their collaboration in intelligent industrial operations and maintenance. Through integrated solutions that combine industrial sensing hardware, software platforms, and industry-specific AI models, the partnership aims to lower adoption barriers and accelerate real-world deployment.

Industrial maintenance is evolving from experience-driven practices to a future powered by data, AI, and digital twins. DataMesh remains committed to working with global partners to deliver practical, scalable solutions that make industrial systems safer, more efficient, and more predictable.