DataMesh Launches the New Inspector, Advancing Digital Twin–Driven Intelligent Operations

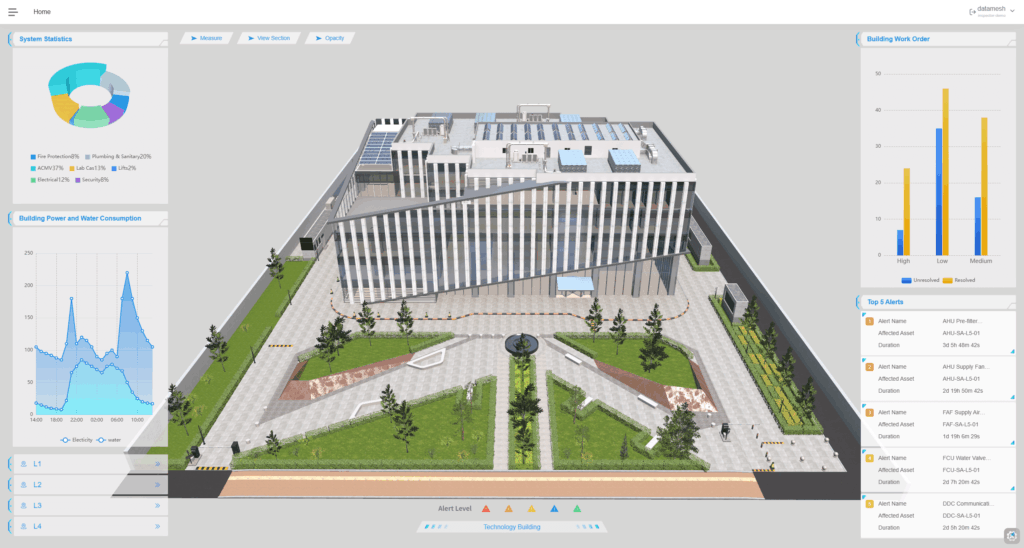

DataMesh announced the global release of the new DataMesh Inspector (Version 2601, Internal Version 8.0.0), a digital twin–powered intelligent operations and maintenance platform designed for industrial enterprises, smart facilities, and critical infrastructure.

DataMesh and Yokogawa Launch an AI-Driven Predictive Maintenance Solution for Industrial Facilities

DataMesh and Yokogawa have partnered to deliver an AI-powered predictive maintenance solution that integrates industrial sensing, AI analytics, and digital twins. The solution enables earlier risk detection, reduces false alarms, and helps operators move from reactive maintenance to proactive prevention.

DataMesh Joins the NVIDIA Omniverse Partner Council JAPAN

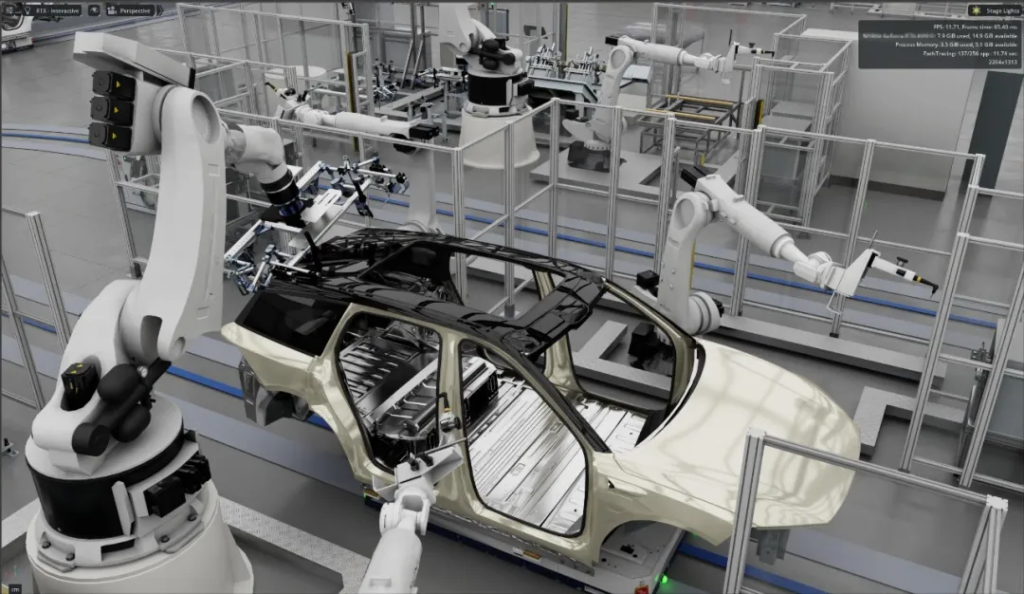

The expanded collaboration unlocks new possibilities for industrial digital twins, physically accurate simulation, and embodied AI—helping manufacturers design, validate, and optimize production with greater speed, confidence, and realism.

DataMesh Recognized as a Tech Innovator in 2025 Gartner® Emerging Tech Report on Intelligent Simulation

DataMesh sees this recognition as a reflection of its ongoing commitment to delivering a practical, user-friendly simulation platform that drives real business value — helping enterprises to improve efficiency, reduce downtime, and optimize decision-making in real time.

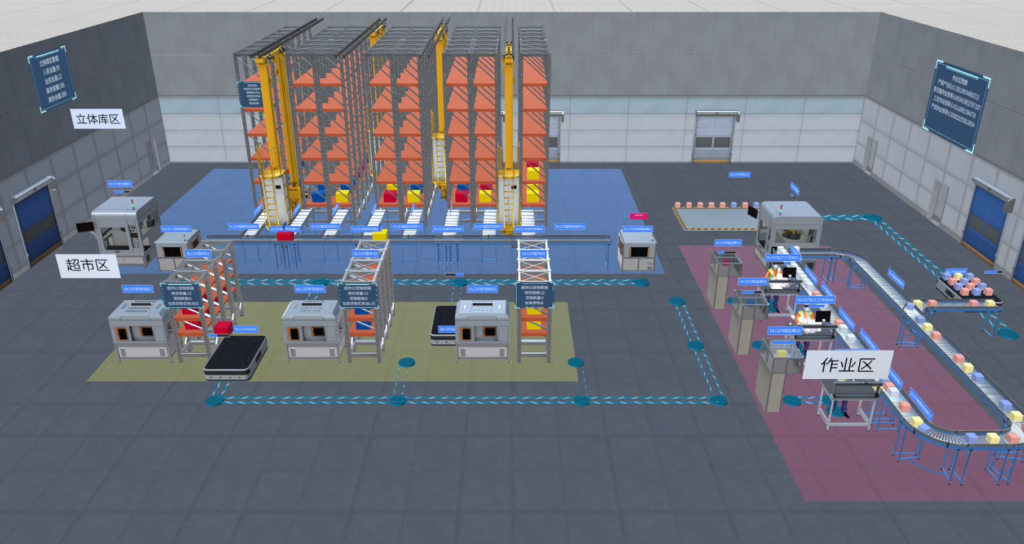

DataMesh FactVerse: Major Update to Warehousing & Logistics DLC – Empowering Digital Transformation

The DataMesh FactVerse Platform Industry DLC – Warehousing & Logistics DLC has been upgraded with a variety of new 3D models tailored for the warehousing & logistics sector, providing an out-of-the-box digital twin solution to optimize the entire operational process.

DataMesh Showcases Simulation Digital Twins Powered by DataMesh FactVerse and NVIDIA Omniverse at GTC 2025

FactVerse to further support enterprises to build high-quality simulation digital twins and AI solutions with NVIDIA Omniverse technologies, and introduce a new NVIDIA Omniverse extension, to seamlessly connect FactVerse to applications developed on Omniverse.

Introducing DataMesh FactVerse Implementation: Modular, Low-Code, and Data-Driven

This article explores how DataMesh FactVerse Implementation empowers enterprises to accelerate their digital twin initiatives with a modular, low-code, and data-driven approach—driving ROI, reducing costs, and increasing efficiency.

FactVerse + Omniverse: Building a Spatiotemporally Consistent Simulation Digital Twin and AI Business Platform

DataMesh is now working closely with NVIDIA to integrate the strengths of FactVerse and NVIDIA Omniverse, making the deployment of digital twins more efficient, sustainable, and user-friendly. This collaboration aims to empower key stages of manufacturing, ultimately enhancing operational efficiency.

DataMesh FactVerse Powers NIO’s Smart Factory Transformation with Digital Twins

In collaboration with DataMesh, NIO deployed a Production Management Center (PMC) digital twin platform for its vehicle assembly line. Powered by FactVerse, this platform transforms production management by enabling comprehensive simulation and real-time monitoring of the entire production process within a highly detailed 1:1 digital twin factory.

DataMesh Among the Top 10 Finalists in the 2024 NVIDIA Inception Showcase – Final Showcase

We have made it to the Top 10 Finalists of the 2024 NVIDIA Inception Showcase. The event attracted over 300 startups nationwide, and we’re proud to be recognized for our pioneering innovation in simulation digital twins.