DataMesh FactVerse 7.2 Updates: Build a Digital Twin Factory That Works, Not Just Looks

The 7.2 updates bring enhanced tools and features, empowering enterprises to create intelligent digital twin scenarios with greater efficiency. From streamlined scenario design to immersive training modules, these updates advance digital transformation and operational innovation.

Collaboration Between JTC & DataMesh: Advancing Construction Efficiency with Digital Twin and Mixed Reality

By integrating BIM data with MR technology, the platform empowers frontline workers to visualise and understand complex construction tasks in both virtual and real-world spaces, significantly improving efficiency on job sites.

Accelerating Industrial Metaverse: FactVerse Updates August 2024

FactVerse platform introduces valuable enhancements and optimizes performance for frontline business scenarios to help enterprises integrate digital twin technology into their operations more efficiently, driving progress toward intelligent manufacturing, smart maintenance, and sustainable development.

Inspector 1.2 Released: Uncover Hidden Building and Facility Information for Smart Management with Mixed Reality

Quickly generate digital twin scenes, dynamically load BIM data on the go, and effortlessly inspect hidden details behind devices and equipment. With DataMesh Inspector 1.2, managing and maintaining buildings has never been easier.

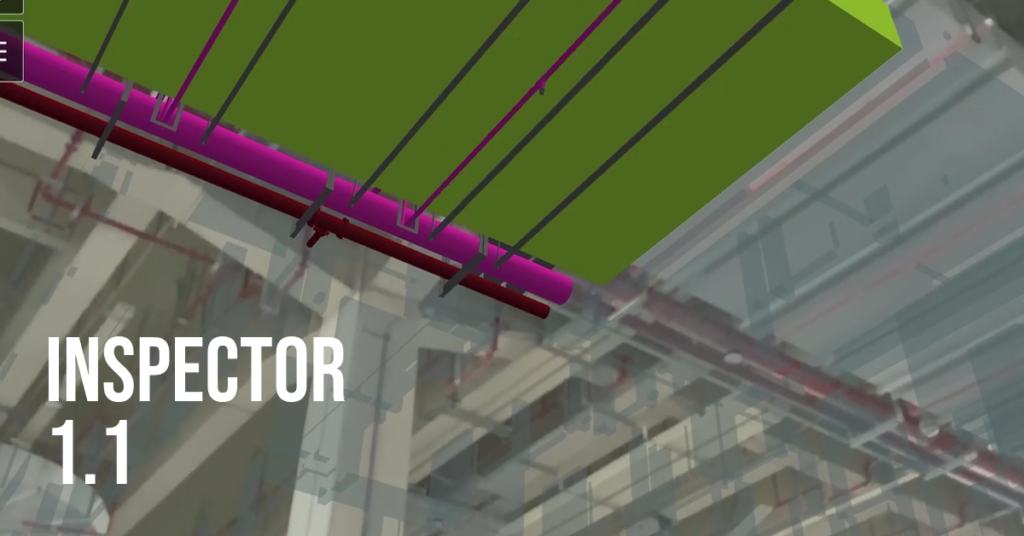

DataMesh Inspector 1.1 Releases, Enhancing Collaboration and MR Experience in AEC

Streamlining and optimizing key aspects, including visualization, on-site collaboration, and resource management, Inspector empowers construction and engineering professionals to achieve higher project execution efficiency throughout the AEC lifecycle.