How Can We Help?

Quick Start: Build a Digital Twin Scene

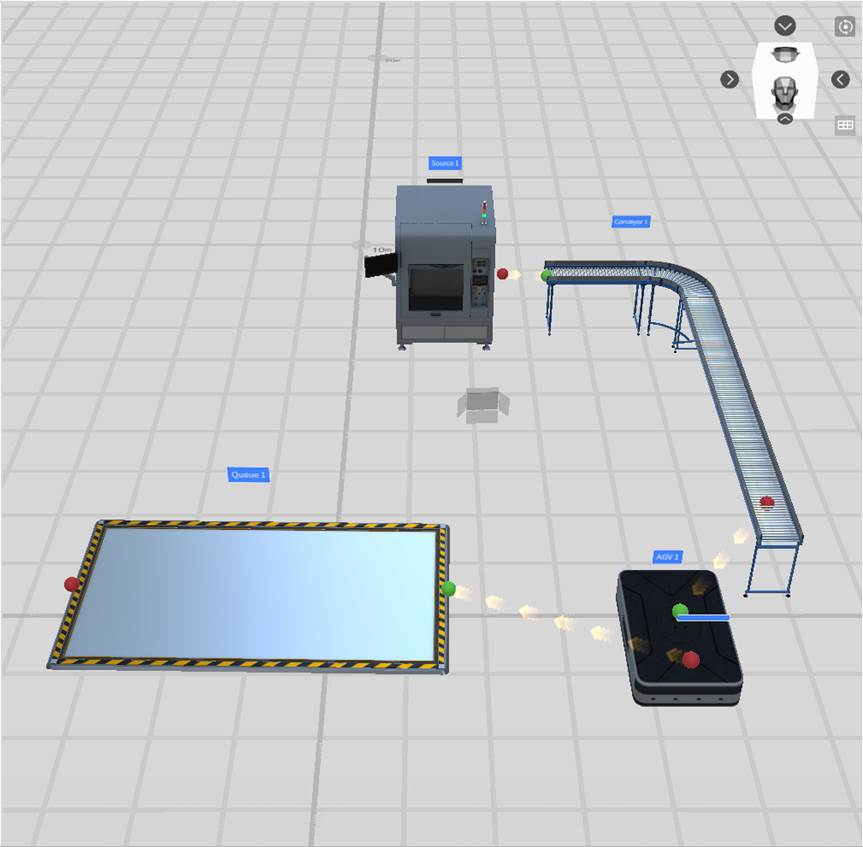

This chapter will demonstrate the basic workflow of building a digital twin scene using FactVerse Designer through templates and models from FactVerse DLCs. Through the following examples, you will learn about the key steps in creating a digital twin scene.

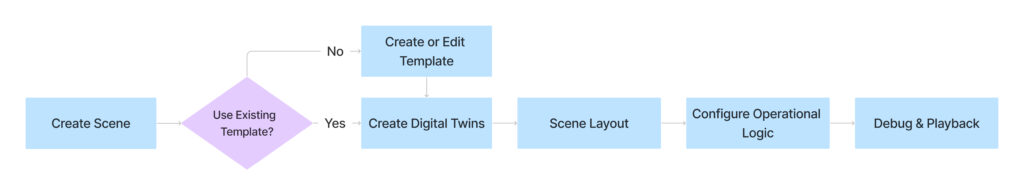

Basic Workflow

- Create Digital Twin Templates

- Use Preset Templates: If you are using preset templates from a FactVerse DLC, this step can be skipped.

- Custom Templates: If you need to create a custom digital twin template, refer to the Create Digital Twin Template section for detailed guidance.

- Create Digital Twins

- Based on the selected template, you can manually create individual twins or generate multiple instances in batch to support large-scale production environments.

- Scene Layout and Connection Configuration

- Layout Planning: Arrange the positions and layout of twins to ensure collaboration within the scene.

- Configure Connections: Define connections between twins to determine the direction of product flow or logistics.

- Configure Operational Logic

- Attribute Settings: Configure twin attributes to accurately simulate their behavior in real-world factory operations.

- Path Planning: Assign movement paths to digital twins so they can operate and transport along predetermined routes.

- Behavior Tree Editing: Use the Behavior Tree Editor to define twin interactions and actions.

- Debug and Playback

- Run and Inspect: Run the configured digital twin scene in FactVerse Designer to observe the overall operation.

- Debug Scene Behavior: Use pause, step-by-step playback, and other tools to check interaction logic, path movement, and state changes between twins, identifying potential issues.

- Validate Simulation: Verify whether the simulation meets design objectives by observing attribute changes, color changes, and triggered actions.

Create Digital Twins Using Templates from the Virtual Factory DLC

This section demonstrates how to use templates from the Virtual Factory DLC to quickly create the following common digital twins:

- A flat roller conveyor

- A source

- An AGV

- A queue

Through this example, you will learn the key steps for creating digital twins.

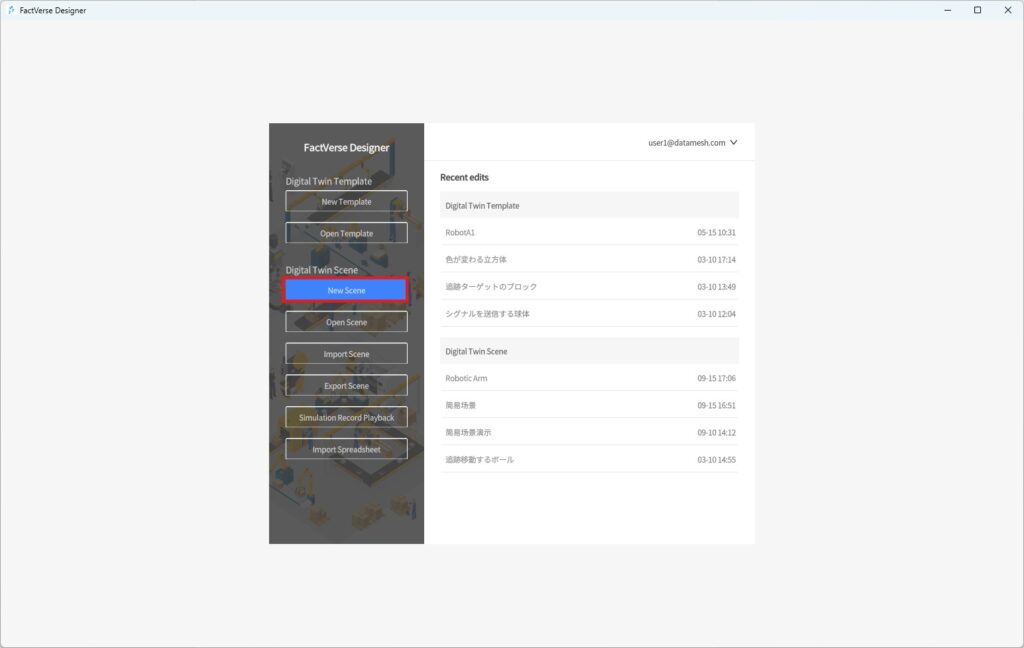

1. Create a New Scene

In FactVerse Designer, click New Scene on the Home Page to open a new scene in the Scene Editor.

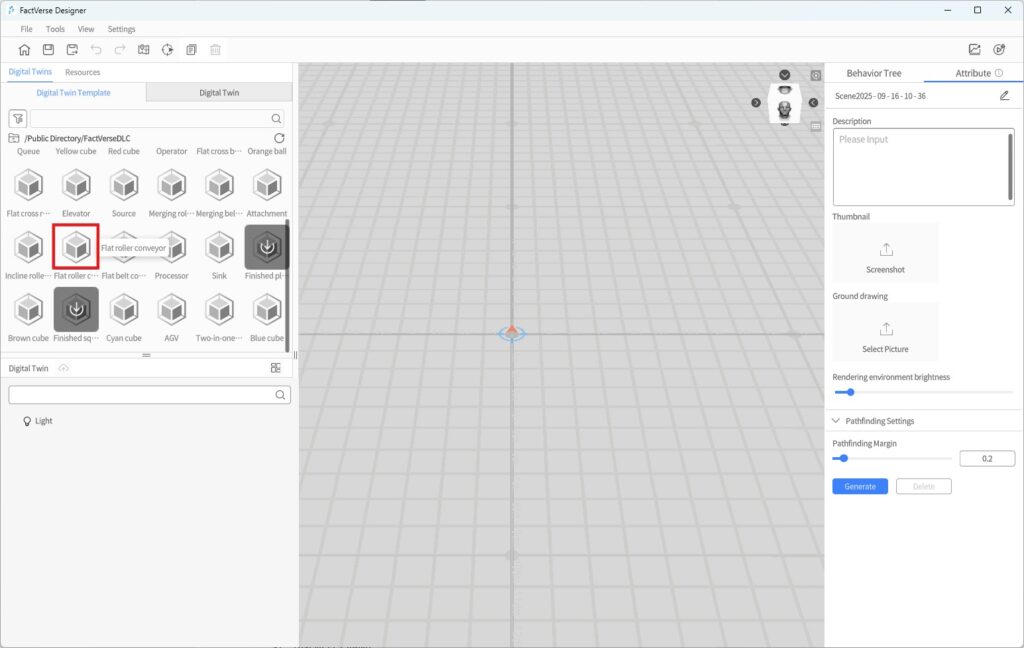

2. Create a Flat Conveyor Belt

a) In Digital Twins Library > Digital Twin Template, expand the path /Public Directory/FactVerseDLC/ and click the Flat roller conveyor

b) In the “Scene Area”, click the desired location to place the conveyor.

c) After placement, right-click to exit placement mode.

3. Create a source

a) In Digital Twins Library > Digital Twin Template, click the template /Public Directory/FactVerseDLC/Source

b) Click the target position in the scene to place the queue.

c) Right-click to exit placement mode after placement.

4. Create a queue

a) In Digital Twins Library > Digital Twin Template, click the template /Public Directory/FactVerseDLC/Queue

b) Click the target position in the scene to place the

c) Right-click to exit placement mode after placement.

5. Create an AGV

a) In Digital Twins Library > Digital Twin Template, click the template /Public Directory/FactVerseDLC/AGV

b) Click the target position in the scene to place the AGV.

c) Right-click to exit placement mode after placement.

6. Save the Scene

Click the Save button![]() in the toolbar to save the scene and name it Simple Demo.

in the toolbar to save the scene and name it Simple Demo.

Scene Layout and Port Connections

This section provides examples to guide you in arranging digital twins within a scene and configuring port connections to simulate production workflows. You will also learn how to debug the setup to ensure that each twin’s logic runs correctly and that the overall process flows smoothly.

Layout Planning

Adjust the positions and dimensions of digital twins according to the actual production process so that the scene accurately reflects the business logic.

Adjust Conveyor Length and Height

You can adjust the length and height of the conveyor belt using the conveyor belt editing tool to suit your requirements. Here are the steps to adjust it:

1. In the Scene Area, select the conveyor and click on Edit.

2. In the editing mode, you can use the conveyor editing tool to stretch the conveyor, adjusting its length, and also modify the conveyor height.

a) Stretching the conveyor: In editing mode, click on one endpoint of the length adjustment line (red) of the conveyor editing tool, then hold down the left mouse button and drag the mouse to adjust the conveyor length.

b) Adjusting conveyor height: In editing mode, click on the height adjustment line (green) endpoint of the conveyor editing tool, then hold down the left mouse button and move the mouse up or down to adjust the conveyor height.

3. Once you finish adjusting, click the End edit button to exit the conveyor editing mode.

4. Click the save button![]() in the toolbar to save the scene.

in the toolbar to save the scene.

Add a New Node to the Conveyor

To add a new node to a conveyor, follow these steps:

- Select the conveyor and click on the Edit button to enter the editing mode.

- In the Scene Area, double-click the mouse on a blank space to add a new node to the conveyor. If you need to delete a node, click on the Delete node option to remove the end section of the conveyor.

- Once you finish adding the node, click the End Edit button to exit the editing mode for the conveyor belt.

- Click the save button

in the toolbar to save the scene.

in the toolbar to save the scene.

Configure Port Connections

In a Virtual Factory scene, to enable goods to be transferred between digital twins along the production line, you need to connect their ports.

This section demonstrates how to connect the following ports:

- Output port of the Source (

) → Input port of the Conveyor (

) → Input port of the Conveyor ( )

) - Output port of the Conveyor (

) → Input port of the AGV (

) → Input port of the AGV ( )

) - Output port of the AGV (

)→ Input port of the Queue (

)→ Input port of the Queue ( )

)

Note: There is no need to connect the output and input ports of the same digital twin.

Steps

- Click on the output port of the Source (

) in the scene, then click on Connect.

) in the scene, then click on Connect. - Move the mouse over the input port of the Conveyor (

) and left click to finish a connection between the output port of the Source (

) and left click to finish a connection between the output port of the Source ( ) and the input port of the Conveyor (

) and the input port of the Conveyor ( ).

).

- Repeat the same process to connect the following input and output ports:

- Output port of the Conveyor (

) and input port of the AGV (

) and input port of the AGV ( )

) - Output port of the AGV (

) and input port of the Queue (

) and input port of the Queue ( )

)

- Click the save button

in the toolbar to save the scene.

in the toolbar to save the scene.

Configure Operational Logic

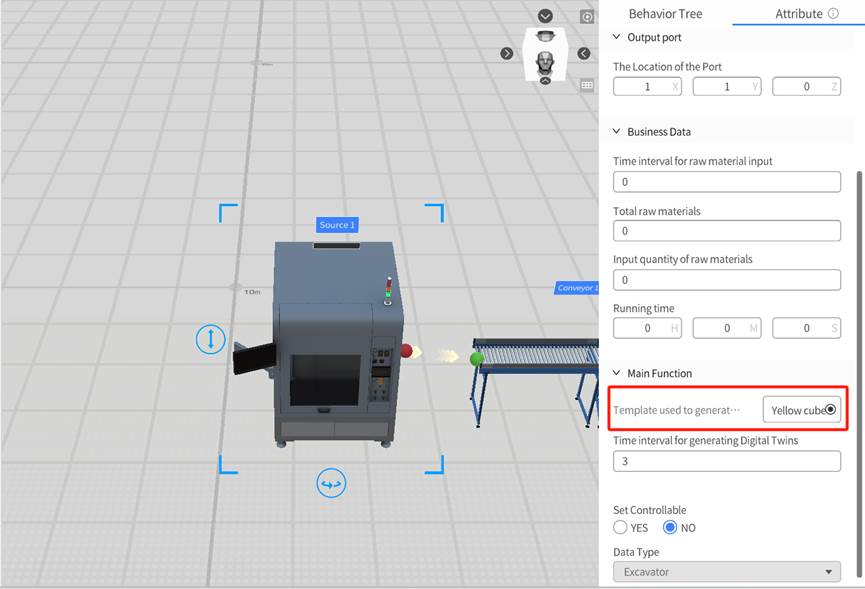

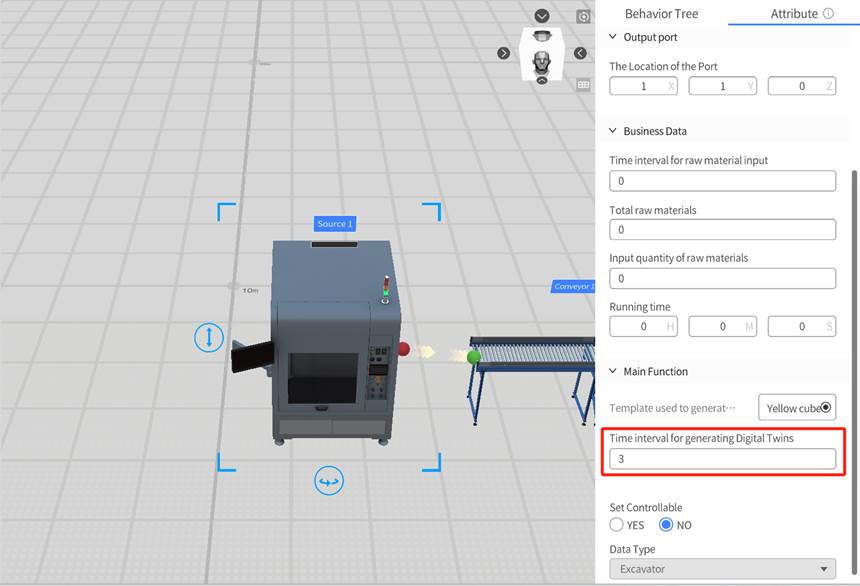

Set the Main Function of the Source

This section describes how to configure the Main Function of the Source so that your Virtual Factory scene can simulate production according to your settings.

Steps

- In the scene area, select the Source.

- In the Attribute Panel, under the Attributes tab, locate the Main Function Next to Template used to generate digital twins, click the Edit button. In the template list that opens, choose a product-type template from the resource pack. The Source will then generate items according to this template.

- Modify the Time interval for generating digital twins (i.e., the time interval at which the Source produces items). Set the interval to an appropriate value to simulate the production rhythm of a real factory.

- Click the save button

in the toolbar to save the scene.

in the toolbar to save the scene.

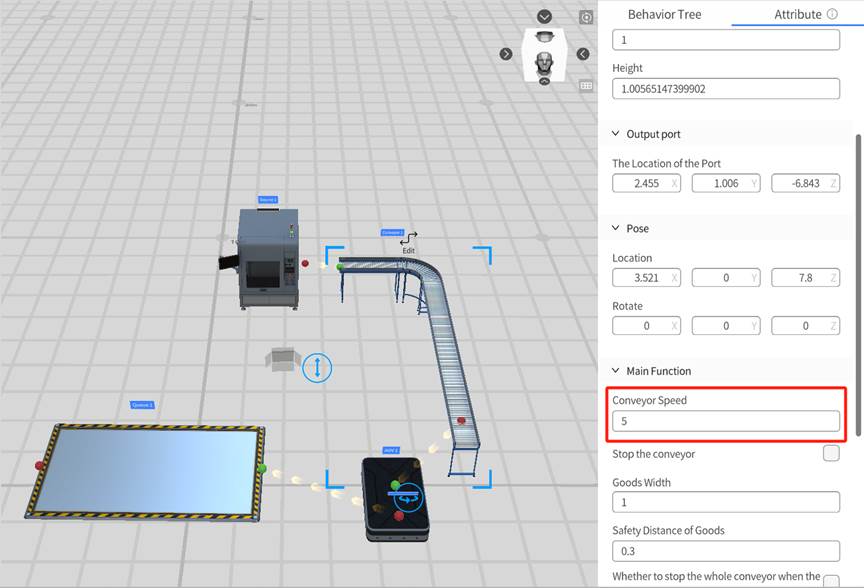

Modify Conveyor Speed

In this section, the conveyor speed will be adjusted to 5 m/s, allowing the conveyor to operate at a faster speed during the simulation.

- In the Scene Area, click to select the conveyor.

- In the Attribute Pane, modify the value of the Conveyor Speed to “5.”

- Click the save button

in the toolbar to save the scene.

in the toolbar to save the scene.

Create a Driving Path for the AGV

Creating a driving path for the AGV allows it to move along a predefined route. Follow these steps to create the AGV’s driving path:

- Click the Path Mode button

in the toolbar to open the Path Mode interface.

in the toolbar to open the Path Mode interface. - Click the button

in the toolbar to enter Construction Mode.

in the toolbar to enter Construction Mode. - In the scene area, click three different locations to create three path points for the AGV’s driving route:

- point0: Pickup location

- point1: Delivery location

- point2: Charging location

- Click the Select button

in the toolbar to enter Select Mode.

in the toolbar to enter Select Mode. - Select the connection line between point0 and point1, and set the connection direction to Bidirectional (↔).

- Select the connection line between point1 and point2, and set the connection direction to Bidirectional (↔).

- Click < Exit to close the Path Mode interface and return to the Scene Editor. A prompt window will appear to save the path.

- In the prompt window, click Yes to save the path.

- Click the save button

in the toolbar to save the scene.

in the toolbar to save the scene.

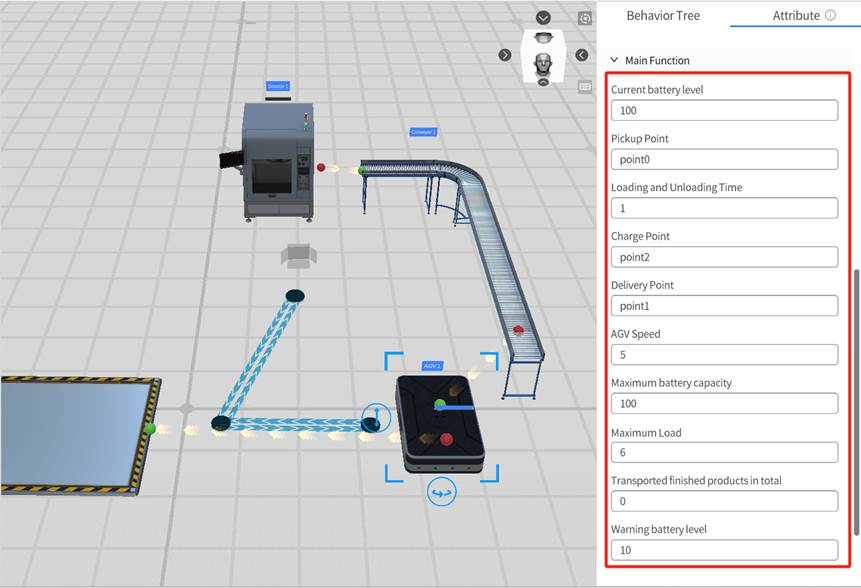

Configure the Main Function of the AGV

Setting the main function of the AGV ensures that it follows the predefined path and parameters to execute tasks.

Follow these steps to set the main function of the AGV:

- In the Scene Area, select the AGV.

- Set the moving path of the AGV.

- Change PickUp Point to the previously set path point name, e.g., point0.

- Change Delivery Point to the previously set path point name, e.g., point1.

- Change Charge Point to the previously set path point name, e.g., point2.

- Set the AGV speed to “5.”

- Set the Maximum load to “6” (indicating that it can carry up to 6 items).

- Loading and Unloading Time to “1” (representing the time taken to load or unload goods, which is 1 second).

- Click the save button

in the toolbar to save the scene

in the toolbar to save the scene

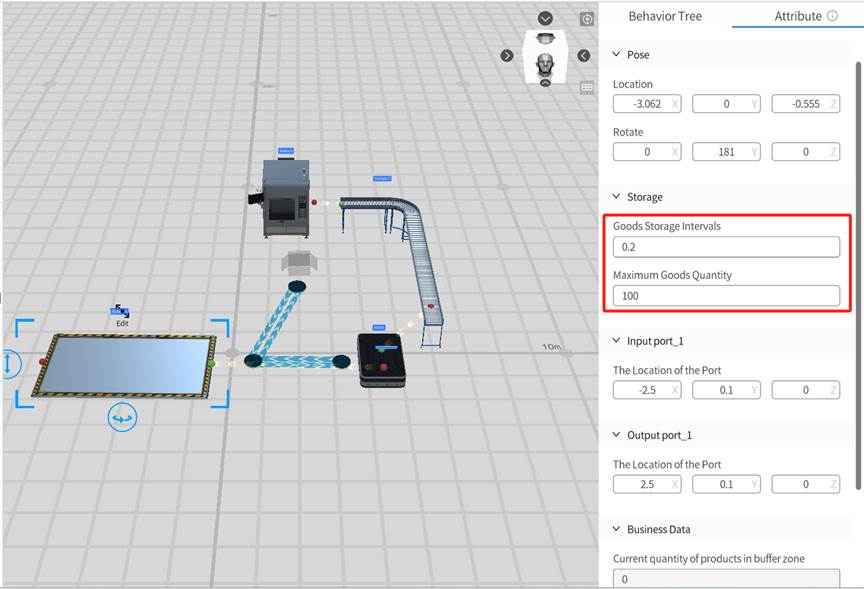

Configure the Queue

The Queue is used to hold goods, and its capacity and storage rules can be controlled through configuration settings.

Configuration Options:

- Maximum Goods Quantity: Set the maximum number of goods that can be stored in the Queue.

- Goods Storage Interval: Define the distance between each storage unit. The Queue automatically divides storage units based on the Goods width, Goods length, and Goods height of the Queue template. Each storage unit can hold a maximum of 1 item.

Preview the Scene Playback

You can preview the scene and adjust playback settings by following these steps:

- Click the Debug Playback button

in the Scene Editor toolbar to start previewing the scene and view the overall effect.

in the Scene Editor toolbar to start previewing the scene and view the overall effect. - During playback, use the playback progress bar to control the playback speed. To pause playback, click the Pause

- Click the Exit button

to exit playback mode.

to exit playback mode.