Struggling to boost productivity? Frustrated by equipment issues that only surface too late?

The all-new FactVerse takes a major leap forward, seamlessly integrating simulation and data analytics. With this upgrade, enterprises can spot potential problems early, test plans virtually, and make better business decisions.

As an AI-driven simulation digital twin platform, FactVerse empowers organizations with capabilities that cover the entire lifecycle—virtual planning and design, real-time monitoring and operations, intelligent training and guidance, and predictive maintenance. With its low-code environment and composable architecture, FactVerse is fast to deploy, easy to scale, and delivers measurable results—faster and more cost-effectively.

This September, FactVerse introduces a host of powerful new features. The biggest highlight: a major upgrade to the Data Fusion Services (DFS), now deeply integrated with the simulation capabilities of FactVerse Designer. The result? Enterprises can not only see operations play out in 3D but also transform simulations into interactive dashboards and analytical insights—making it faster and easier to find the best course of action.

Highlight 1:

Smart Simulation + Data Dashboards

Plan Virtually. Validate Faster. Spend Less.

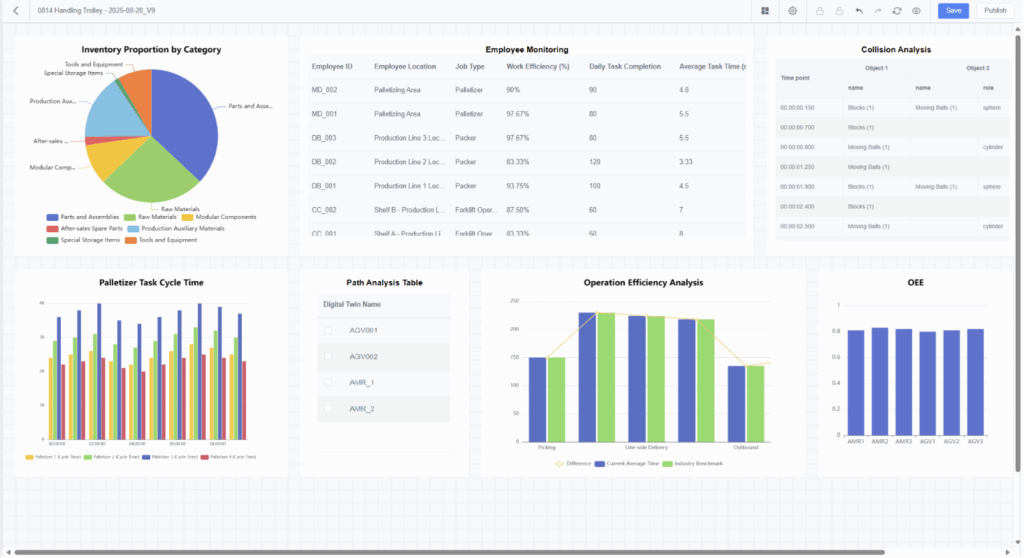

From factory layouts to production line optimization and logistics scheduling, enterprises need to quickly test and validate multiple scenarios. With FactVerse, users can easily adjust logic and parameters to run collaborative simulations across digital twins—pinpointing the most efficient plan in less time.

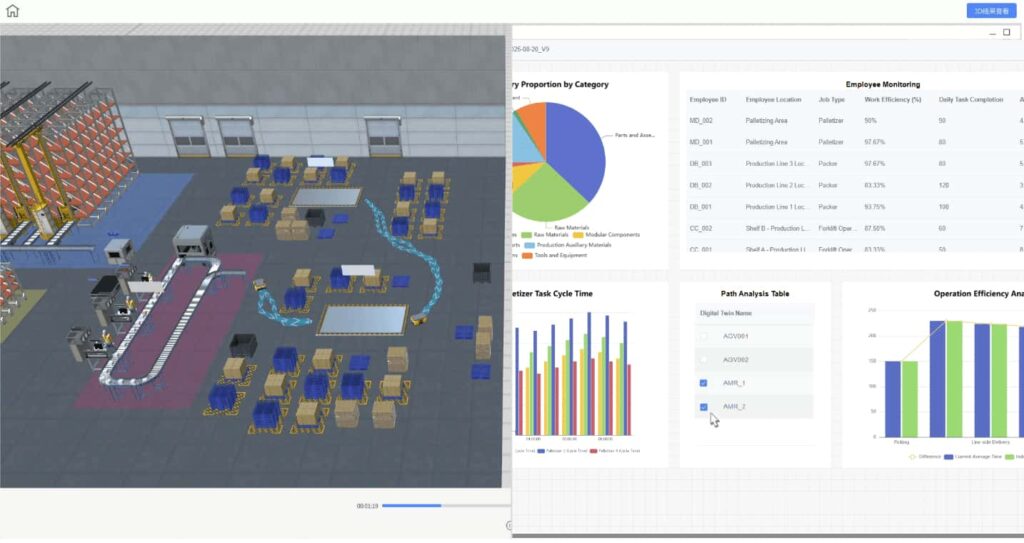

The upgraded FactVerse Designer adds Pathfinding simulation, enabling smart route planning in complex environments. Digital twins automatically calculate and execute optimal routes, delivering efficiency metrics that help teams identify the best configuration.

Even better, this feature works seamlessly with other elements in a scene. For example, in warehouse and logistics scenarios, you can simulate conveyors, goods, shelves, AGVs, and AMRs working together—monitoring collision risks in real time while tracking critical KPIs such as Overall Equipment Effectiveness (OEE).

Most importantly, results go beyond 3D scene visualization. With DFS, they turn into multi-dimensional dashboards and 3D path reviews—making it easy to compare scenarios, evaluate performance differences, and quickly choose the winning plan.

Highlight 2:

Real-Time Analytics + AI Anomaly Detection + Smart Alerts

Stay Ahead with Predictive Maintenance

For asset-heavy industries, maintenance is a constant balancing act: too early, and costs go up; too late, and downtime is devastating.

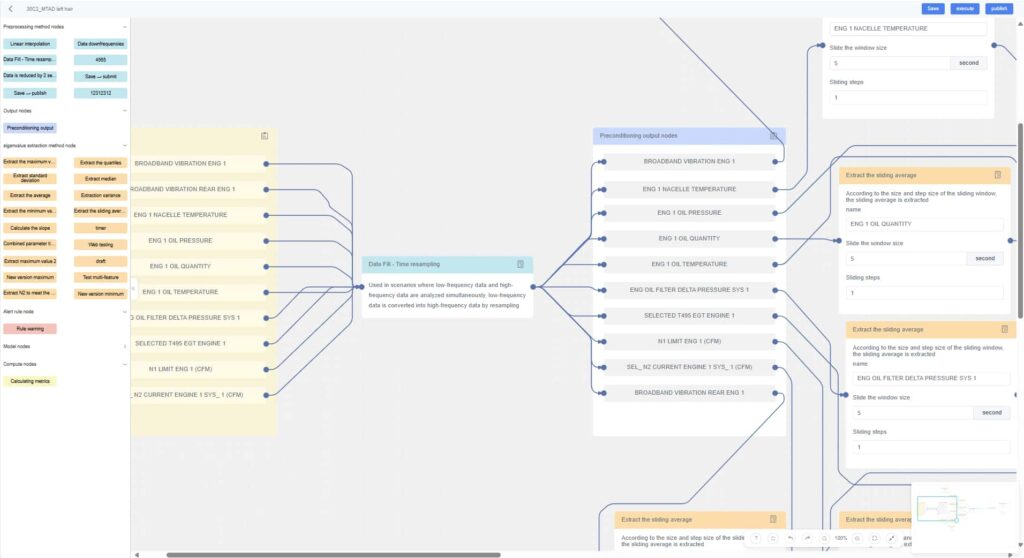

The upgraded DFS combines real-time equipment data with digital twin models to deliver deeper, smarter analysis. Instead of relying on single metrics, engineers can analyze multiple data features together, applying custom alert rules to spot anomalies earlier.

With AI-powered detection, DFS automatically recognizes abnormal patterns, triggers alerts, and highlights equipment that needs attention. Combined with digital twin models, the system pinpoints the faulty asset and its upstream/downstream connections—helping maintenance teams act before breakdowns happen, and avoiding costly unplanned downtime.

Highlight 3:

Comparisons + Traceability

Smarter Monitoring. Faster Optimization.

DFS also elevates real-time production monitoring. For example, if cycle times creep up or energy usage rises, DFS detects the trend and sends alerts before capacity is impacted.

Meanwhile, upgraded simulation extends into daily operations. When production underperforms, teams can simulate ideal conditions with digital twins and compare them directly to real performance. This makes it easy to spot gaps, trace root causes, and optimize fast—closing the loop from monitoring to resolution.

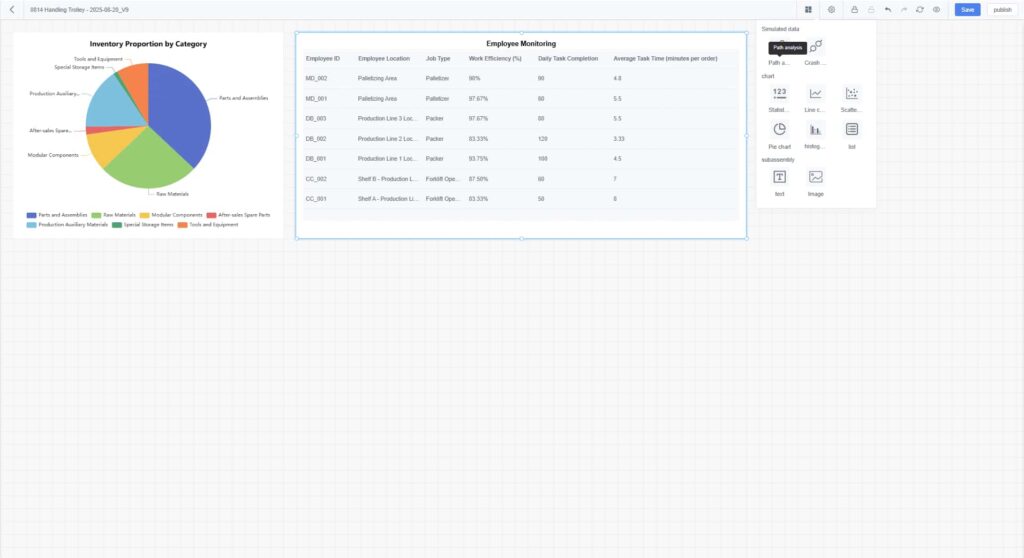

Data Insights Made for Everyone

The new DFS makes advanced analytics accessible to all teams, not just data scientists:

- Drag-and-drop analysis canvas: Explore data visually, without writing code.

- Built-in method library: Pre-loaded with common models and algorithms—ready to use and easy to customize.

- Custom dashboards: Quickly build the charts you need—dual-axis, pie, bar, and more.

- Knowledge capture: Turn engineers’ expertise and industry know-how into reusable assets, building a long-term competitive advantage.

With these tools, organizations can democratize data-driven decision-making—empowering everyone to contribute to continuous optimization.

A Complete End-to-End Loop

With the combined upgrades to DFS and Designer, FactVerse now supports the entire optimization cycle:

data ingestion → scenario simulation → comparative analysis → solution optimization → real-time monitoring → root cause traceability.

This “see it, measure it, improve it” platform helps enterprises continuously unlock new levels of efficiency and performance.

Looking ahead, FactVerse will further integrate AI and digital twin simulation, unlocking sharper insights and stronger decision-making support. At the same time, it will accelerate innovations in industrial robotics, embodied intelligence, and next-generation industrial AI applications—helping enterprises move confidently into a smarter, more efficient future.

Try It Today!

Ready to experience the new FactVerse? Apply for a Free Trial today. To learn more about our digital twin–powered solutions, contact us at service@datamesh.com.