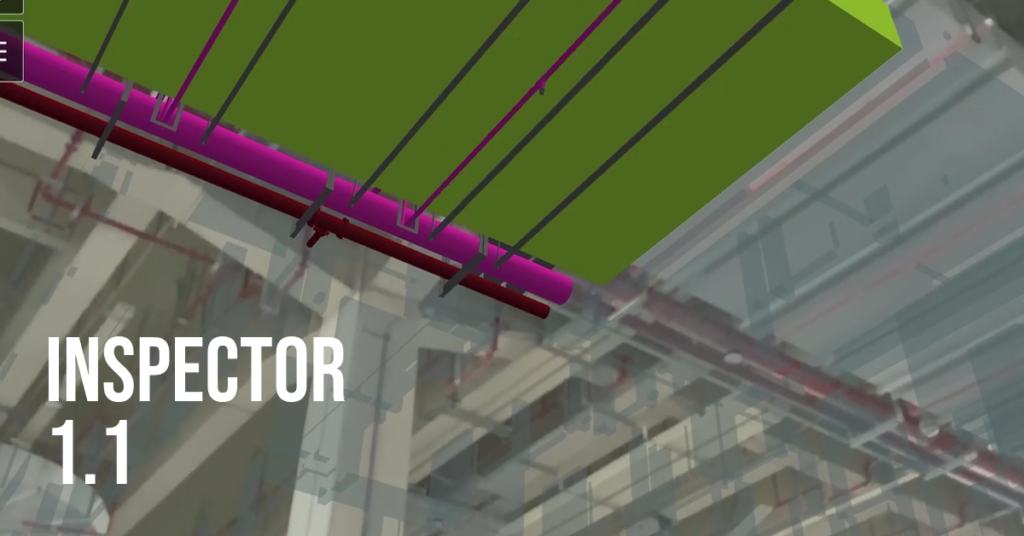

DataMesh Inspector 1.1 Releases, Enhancing Collaboration and MR Experience in AEC

Streamlining and optimizing key aspects, including visualization, on-site collaboration, and resource management, Inspector empowers construction and engineering professionals to achieve higher project execution efficiency throughout the AEC lifecycle.

DataMesh Director 6.1 Released, Now Supporting Lenovo ThinkReality VRX

Pushing the boundaries of 3D+XR process design and enterprise training, DataMesh Director is now compatible with Lenovo ThinkReality VRX through the Snapdragon Spaces XR developer platform.

Digital Twin + XR Projection Tour of “TOKYO TORCH/Torch Tower” Successfully Concluded

Aimed at verifying the visualization effects of the planned building through the use of Digital Twin and XR, the event held at the planned site of the “Torch Tower,” has received positive feedback from various stakeholders.