DataMesh Joins the NVIDIA Omniverse Partner Council JAPAN

The expanded collaboration unlocks new possibilities for industrial digital twins, physically accurate simulation, and embodied AI—helping manufacturers design, validate, and optimize production with greater speed, confidence, and realism.

Jebsee Accelerates Production Line Automation Planning with DataMesh FactVerse, Cutting Risk and Boosting Communication

Jebsee, a leading Taiwanese manufacturer of automotive antennas and communication modules, used DataMesh FactVerse to simulate production line automation upgrades and reduce planning risk. The platform improved communication, delivered data-driven insights, and helped boost throughput while building a reusable digital foundation for future growth.

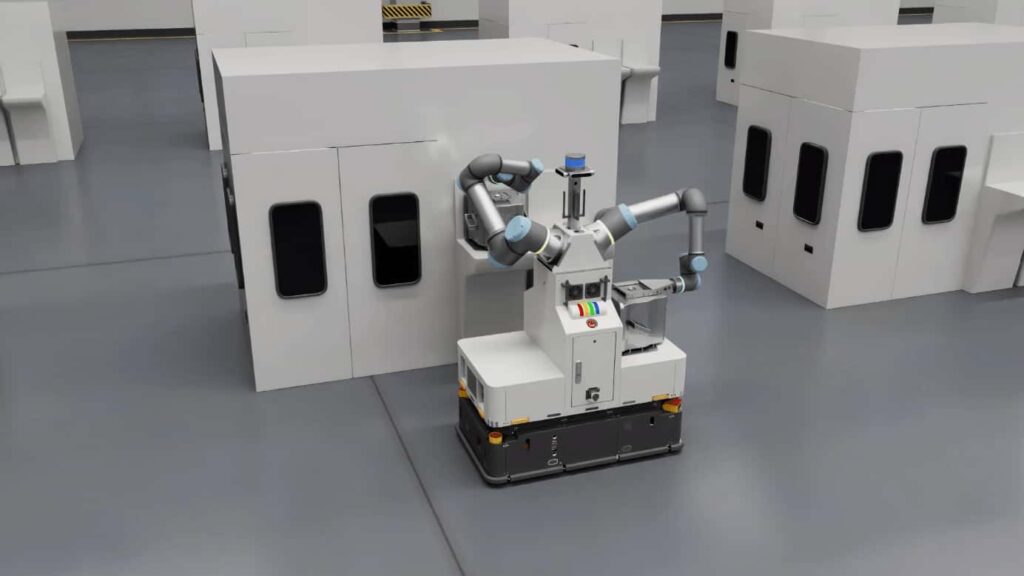

Gyro × DataMesh: Making Intralogistics Automation Solutions Easier to Understand, Validate, and Implement with Digital Twins

Gyro, a leading AMR and smart intralogistics provider in Taiwan, partnered with DataMesh to deliver a digital-twin-powered simulation approach—built on FactVerse and NVIDIA Omniverse—that helps customers see automation value upfront and make decisions faster.

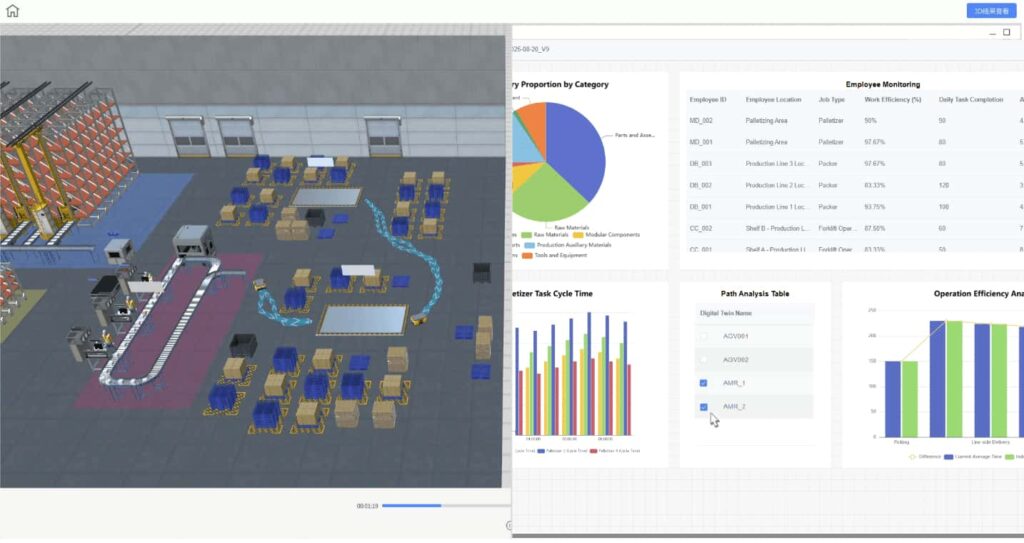

DataMesh FactVerse September Update: Smarter Decisions Powered by Integrated Simulation and Data Analytics

A major upgrade to the Data Fusion Service (DFS) now brings deep integration with FactVerse Designer’s simulation capabilities. Enterprises can not only visualize operations in 3D but also turn simulations into interactive dashboards and insights—accelerating smarter, faster decision-making.

DataMesh Recognized as a Tech Innovator in 2025 Gartner® Emerging Tech Report on Intelligent Simulation

DataMesh sees this recognition as a reflection of its ongoing commitment to delivering a practical, user-friendly simulation platform that drives real business value — helping enterprises to improve efficiency, reduce downtime, and optimize decision-making in real time.

DataMesh Showcases Simulation Digital Twins Powered by DataMesh FactVerse and NVIDIA Omniverse at GTC 2025

FactVerse to further support enterprises to build high-quality simulation digital twins and AI solutions with NVIDIA Omniverse technologies, and introduce a new NVIDIA Omniverse extension, to seamlessly connect FactVerse to applications developed on Omniverse.

Introducing DataMesh FactVerse Implementation: Modular, Low-Code, and Data-Driven

This article explores how DataMesh FactVerse Implementation empowers enterprises to accelerate their digital twin initiatives with a modular, low-code, and data-driven approach—driving ROI, reducing costs, and increasing efficiency.

FactVerse + Omniverse: Building a Spatiotemporally Consistent Simulation Digital Twin and AI Business Platform

DataMesh is now working closely with NVIDIA to integrate the strengths of FactVerse and NVIDIA Omniverse, making the deployment of digital twins more efficient, sustainable, and user-friendly. This collaboration aims to empower key stages of manufacturing, ultimately enhancing operational efficiency.

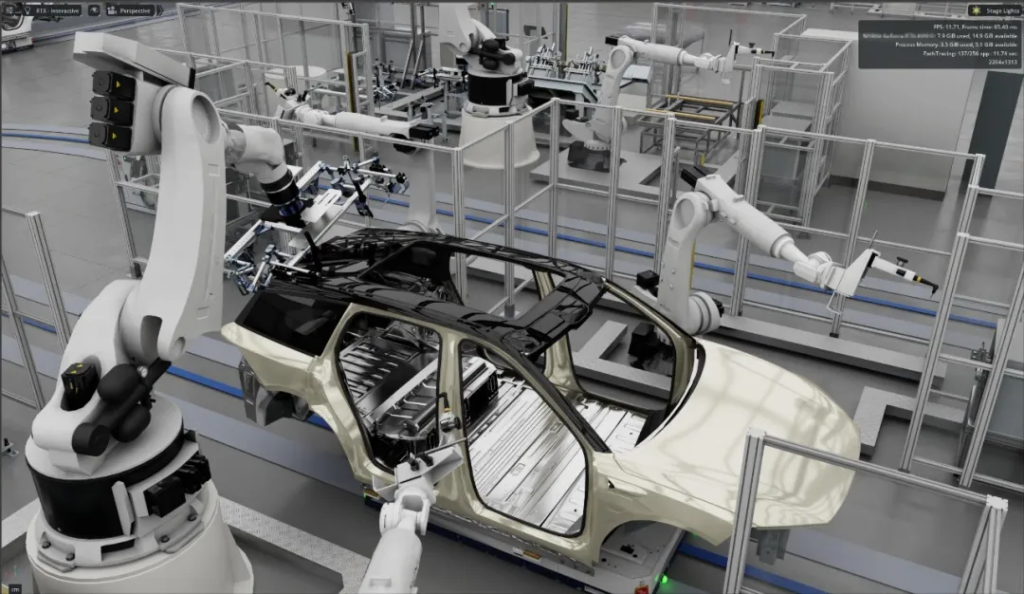

DataMesh FactVerse Powers NIO’s Smart Factory Transformation with Digital Twins

In collaboration with DataMesh, NIO deployed a Production Management Center (PMC) digital twin platform for its vehicle assembly line. Powered by FactVerse, this platform transforms production management by enabling comprehensive simulation and real-time monitoring of the entire production process within a highly detailed 1:1 digital twin factory.

DataMesh Recognized as a Sample Vendor in the 2024 Gartner® Emerging Tech Impact Radar Reports

We believe that being named a Sample Vendor in both Simulation Data and Spatial-Based Digital Twins is a testament to the value of DataMesh and the company’s leadership and contributions in intelligent simulation and industrial metaverse solutions.