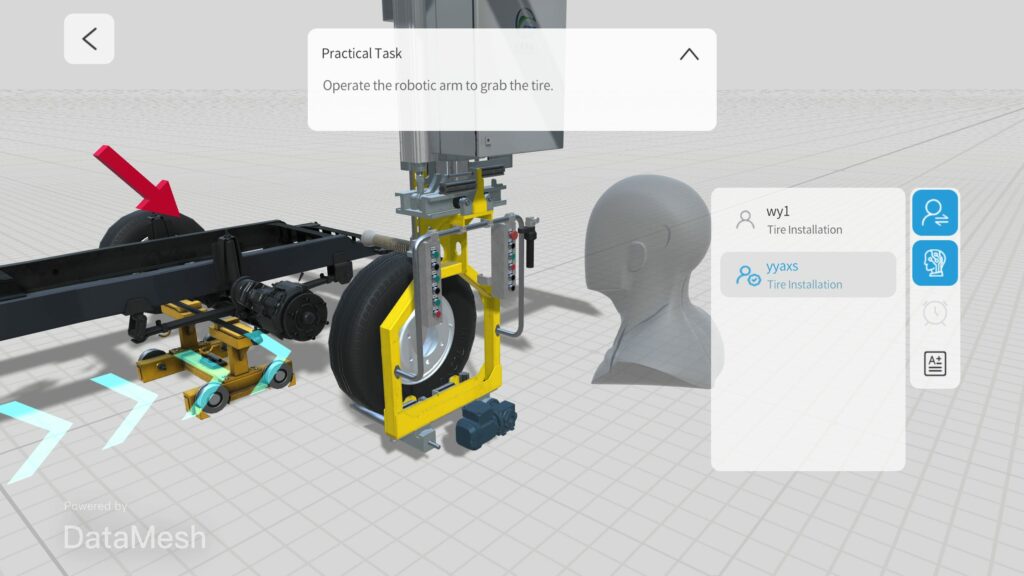

DataMesh Director New Version Released! Major Upgrades to Training Mode

The latest version streamlines the courseware creation process with templated question formats, introduces a new Key Question mechanism to enhance risk management in high-risk industrial training scenarios, along with an invigilation feature that enables real-time monitoring of student performance.

Collaboration Between JTC & DataMesh: Advancing Construction Efficiency with Digital Twin and Mixed Reality

By integrating BIM data with MR technology, the platform empowers frontline workers to visualise and understand complex construction tasks in both virtual and real-world spaces, significantly improving efficiency on job sites.

Inspector 1.2 Released: Uncover Hidden Building and Facility Information for Smart Management with Mixed Reality

Quickly generate digital twin scenes, dynamically load BIM data on the go, and effortlessly inspect hidden details behind devices and equipment. With DataMesh Inspector 1.2, managing and maintaining buildings has never been easier.

FactVerse Express Opens for Global Creators to Innovate in XR Amid Spatial Computing Trend

FactVerse Express is compatible with Apple Vision Pro, ready to empower users across platforms with an exceptional spatial computing experience upon the availability of Apple Vision Pro, in addition to its existing support for various devices, including Meta Quest 3, iPhone, and iPad.

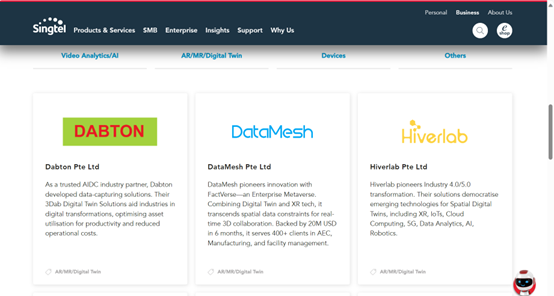

DataMesh: Unleashing Innovation with Singtel’s 5G Partner Ecosystem

The launche of Singtel Business 5G webpage marks a transformative milestone for DataMesh to drive digital business transformation across the Asia Pacific region and beyond, together with Singtel and its a diverse group of collaborative companies.

DataMesh Director 6.1 Released, Now Supporting Lenovo ThinkReality VRX

Pushing the boundaries of 3D+XR process design and enterprise training, DataMesh Director is now compatible with Lenovo ThinkReality VRX through the Snapdragon Spaces XR developer platform.

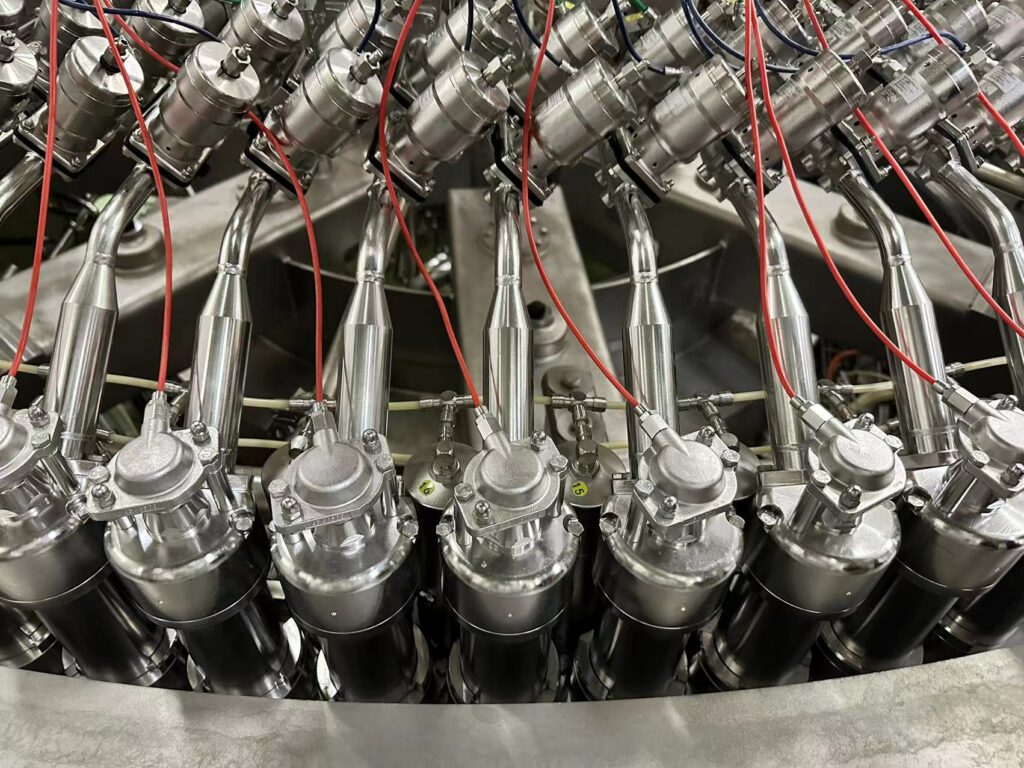

DataMesh Transforms Maintenance Processes for Swire Coca-Cola with 100+ Accelerator

With DataMesh’s digital twin and MR technology, frontline workers now perform complex maintenance tasks more efficiently, reducing downtime and operational costs while creating new job opportunities.