Gyro is a leading AMR and smart logistics provider in Taiwan, serving semiconductor and advanced manufacturing factories. At the start of every intralogistics automation project, giving customers a clear view of the value before they commit is often a key to winning deals.

That’s why Gyro partnered with DataMesh to build an end-to-end digital twin system powered by the FactVerse platform and NVIDIA Omniverse, enabling early validation, high-fidelity presentation, and real-world operational optimization.

With this approach, Gyro can now:

- Show customers clearly what an intralogistics automation upgrade will achieve

- Lower the cost of solution validation and reduce trial-and-error

- Build scalable, repeatable digital twin capabilities

The result: faster decisions, higher confidence, and a stronger competitive edge.

Background: Why Traditional Simulation Falls Short in Modern Smart Factories

As an expert in AMRs and logistics automation, Gyro must help customers quickly evaluate the feasibility and ROI of intralogistics automation upgrades. Previously, Gyro relied mainly on traditional simulation tools. But as factories grow smarter and expectations rise, these tools are showing their age:

- Slow, expensive scenario setup that hinders fast communication

- Outdated scripting that struggles to reflect autonomous AMR behavior

- Poor visuals that no longer meet modern expectations for realism

- Isolated results that can’t support real operations or ongoing optimization

These limitations slowed down sales cycles and complicated project delivery.

The Solution: Digital-Twin-Based Simulation Powered by FactVerse × Omniverse

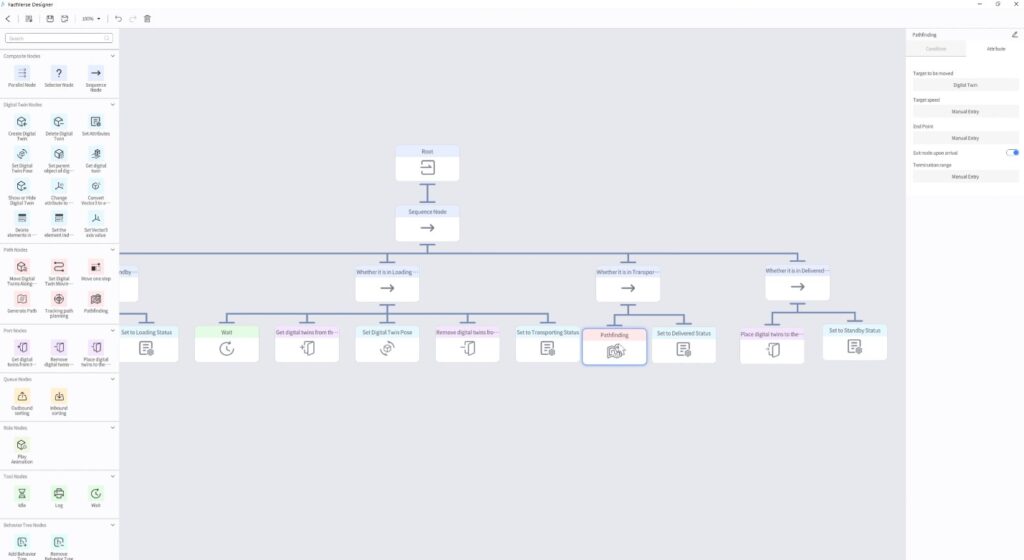

By combining FactVerse’s fast, lightweight simulation with Omniverse’s high-fidelity rendering, Gyro created a seamless workflow that spans validation, presentation, and operational optimization.

1. Fast, Visual Verification of Intralogistics Automation Plans

- Build digital twin production lines using FactVerse’s no-code designer

- Define AMR behaviors with intuitive behavior trees instead of complex scripts

- Use the Data Fusion Services (DFS) for analytics, dashboards, and AI-generated reports

- Run multi-scenario simulations and iterate instantly

“FactVerse’s drag-and-drop tools and behavior trees are perfect for AMR simulation. We no longer need complicated code to recreate AMR logic. Validation is now simpler and much more efficient.”

— Gyro Project Lead

2. High-Fidelity Customer Presentation Through Omniverse

- Showcase lifelike AMR movements and logistics flows

- Visually demonstrate the improvement brought by an intralogistics automation upgrade

“Through FactVerse, we’re now seamlessly connected to NVIDIA Omniverse. Customers immediately see the value of our intralogistics automation proposals — both understanding and trust have noticeably improved. And we’re just getting started with Omniverse’s advanced physics simulation capabilities.”

— Gyro Project Lead

3. Operational Optimization: A Digital Foundation That Extends Beyond Simulation

The same FactVerse scenario built for simulation can continue serving the factory during daily operations:

- Integrate with WMS/MES/dispatching systems for real-time monitoring

- Provide a safe environment for AI scheduling and path optimization

- Support operator training and predictive maintenance

- Validate future capacity expansion or re-layout plans

This transforms Gyro’s intralogistics automation solutions from one-off projects into long-term digital assets that continuously enable optimization.

Gyro now delivers FactVerse as part of every automation project — creating a standardized, scalable, and replicable service product.

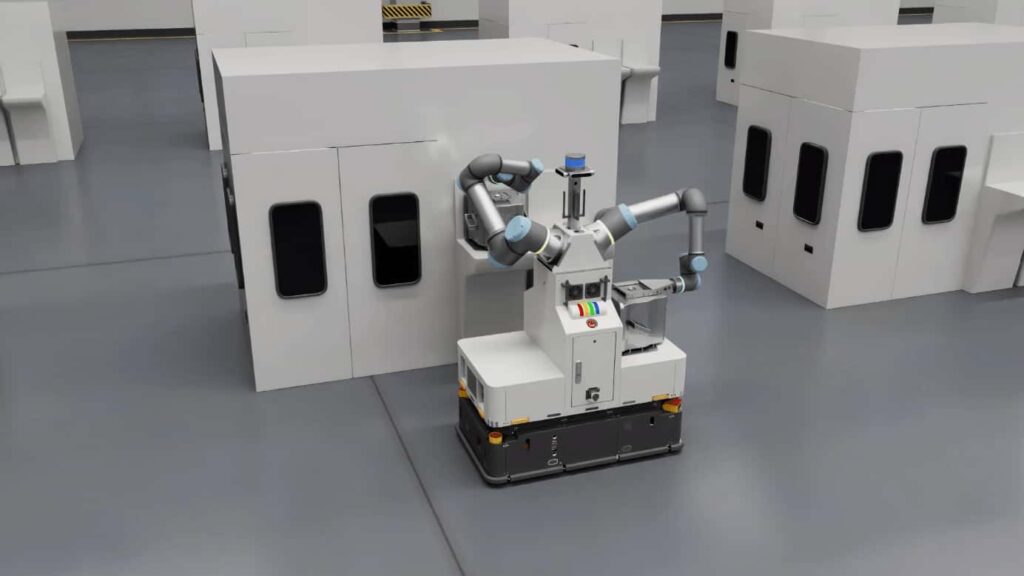

4. Semiconductor Case: Showing AMR Upgrade Value Through Digital Twins

In one semiconductor factory project, Gyro needed to clearly demonstrate the value of its new AMR design.

- Traditional design: 4 storage positions + single robot arm → long material-change cycles and production bottlenecks

- Gyro’s new design: dual storage + dual-arm collaboration → significantly shorter material-change time and smoother line rhythm

FactVerse × Omniverse brought the proposal to life:

Gyro simulated dual-arm coordination, timing differences, machine wait time, and path efficiency under different scenarios. Instead of reading complex parameters, the customer could instantly see the efficiency improvements — the “before vs. after” difference was unmistakable.

This led to faster customer buy-in and smoother implementation.

A Replicable Digital Twin Approach Empowering Automation Providers to Evolve

Through its collaboration with DataMesh, Gyro has developed a repeatable digital twin methodology that spans the full lifecycle of intralogistics automation:

- Pre-sales: more persuasive solution demonstrations, faster customer decisions

- Delivery: earlier issue detection and smoother implementation

- Operations: continuous optimization and scalable future expansion

For automation providers seeking to strengthen delivery capabilities and accelerate customer decision-making, FactVerse × Omniverse is emerging as the new standard for next-generation smart factory.