DataMesh Transforms Maintenance Processes for Swire Coca-Cola with 100+ Accelerator

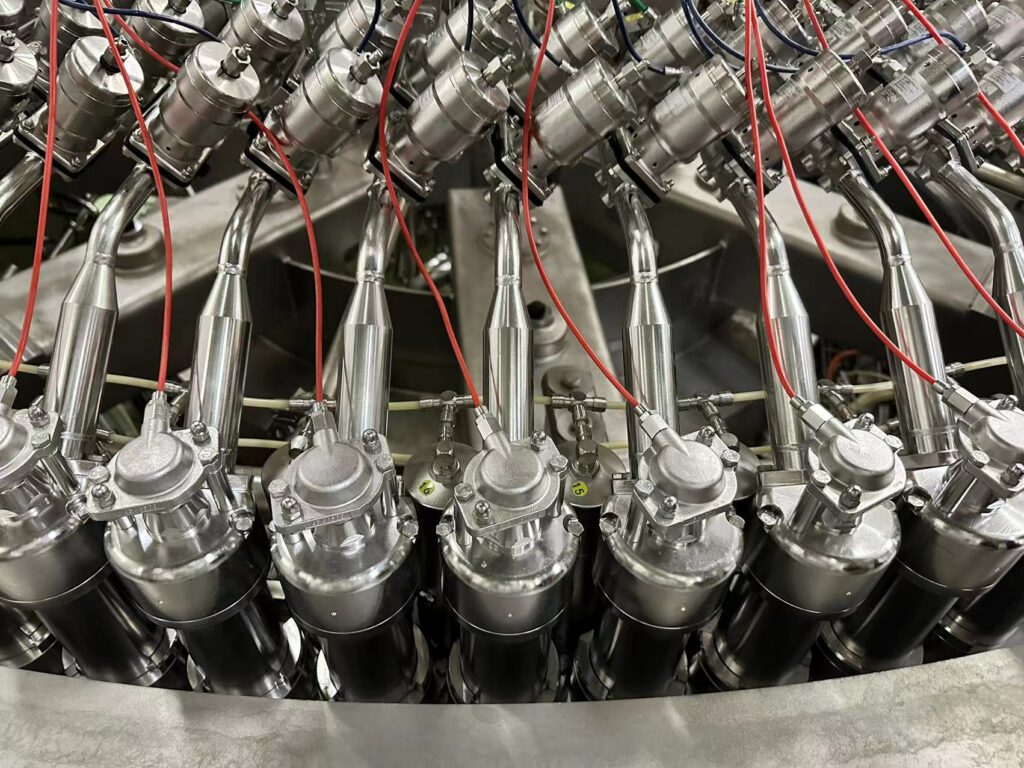

With DataMesh’s digital twin and MR technology, frontline workers now perform complex maintenance tasks more efficiently, reducing downtime and operational costs while creating new job opportunities.