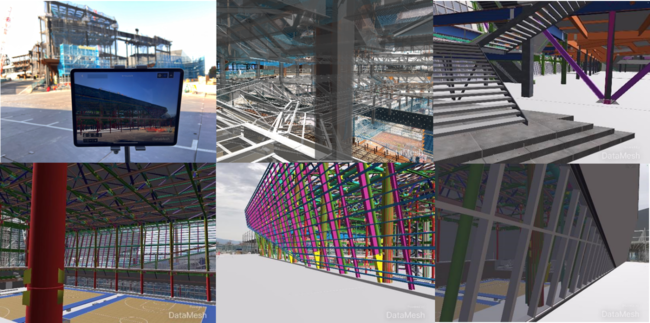

DataMesh + Toda Deployed Digital Twin for Construction Simulation of the SAGA Arena

Digital Twin + MR predicting and verifying changes in site construction processes and methods – Toda and DataMesh today announced the use of BIM and Mixed Reality (“MR”) technology to simulate the construction of the SAGA Arena, which is the main venue for the 2024 Japan National and Paralympic Games. DataMesh Director is currently being used to improve construction efficiency at the SAGA Arena construction site, with data transmission utilizing a 5G communication network provided by NTT DOCOMO.