DataMesh Digital Twin

Product Twin

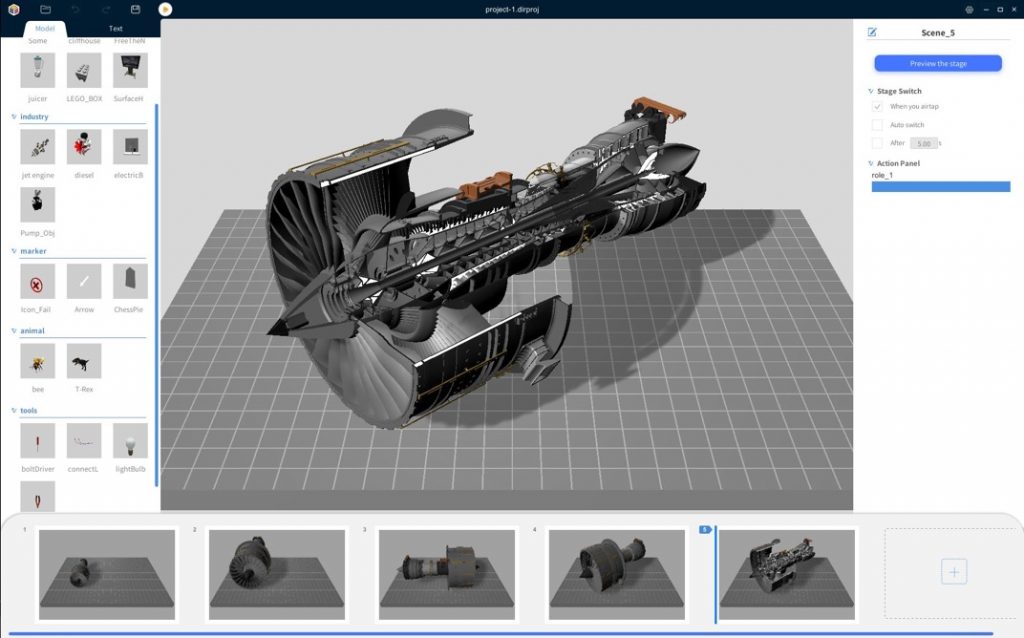

The product and equipment CAD design data can be imported by DataMesh Digital Twin platform and bound to real-time data such as IoT platforms and timing databases to generate Product Twins. A full Product Twin accurately describes the structure and operation SOPs of the equipment in cyberspace and has the real-time status of the product.

Product Twin can be used for assembly teaching, remote support, equipment operation and maintenance, after-sales maintenance guidance, and other scenarios to improve personnel efficiency.

Knowledge Graph & Digital Assistant

DataMesh Digital Assistant integrates business data and knowledge, creates knowledge graph through Machine Learning and NLP, enables first line workers to solve complex problems quickly.

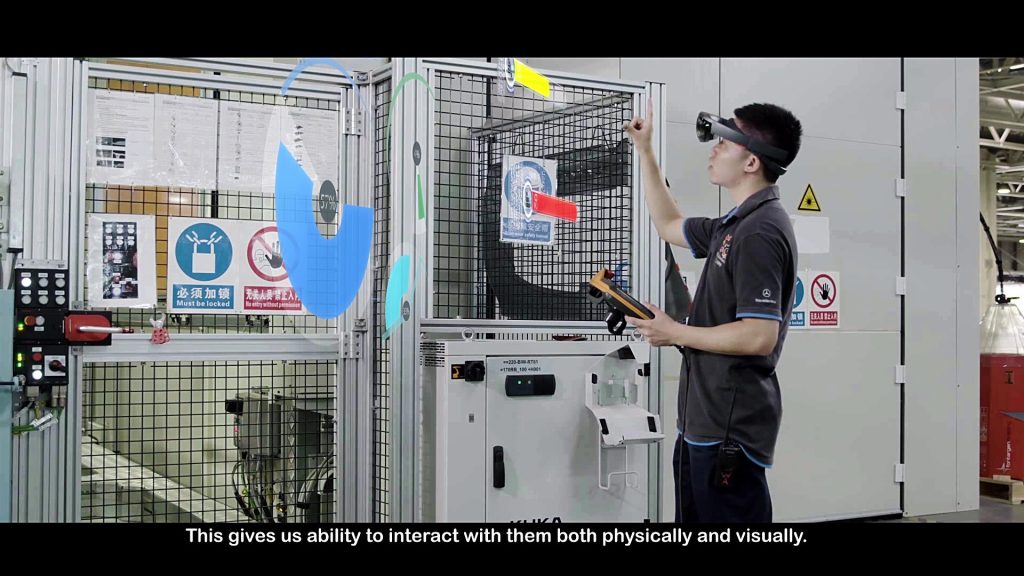

Training & Guidance

DataMesh Director Mixed Reality Training helps users get training scenario data and view and run specific demos from any angle. Users can learn from anywhere without the actual operation of a holographic professor or an interactive shared 3D virtual system.

Customer Cases

SANY

SANY is a world-leading heavy machinery manufacturer. Overseas heavy machinery training and support poses a challenge to further business development due to the lack of professional institutional support.

DataMesh's Digital Twin Simulator Platform enables the customer to address training and support limitations in foreign countries, reducing the cost of energy, maintenance, and training personnel. [Link]

BELLSYSTEM24 & De'Longhi

BELLESYSTEM24 is one of the largest customer support service company in Japan, with 35 self-built call centers, 17,000 fixed-person seats (as of 2020). De'Longhi is one of the leading home appliance maker in Itlay, with subsidaries all over the world. By building and adopting a next-generation product call and support platform with DataMesh Director and Cloud services, BELLSYSTEM24 and De'Longhi are revolutionizing the future of the call center and support experience. It significantly reduces support cost, improve productivity, enable remote work possibility, and enhancing market competitiveness. [Link]

Obayashi Corporation (大林组)

In the construction industry, there is a concern that a large number of workers will leave the industry due to a decline in the number of workers and the aging of the workforce, as well as a large disparity in working hours compared to other industries due to the impact of working on weekends.

Obayashi Corporation adopted XR technology, but since the original system mainly displays the completed form of the construction work, its use in on-site work has been limited.

Together with TIS and DataMesh, Obayashi Corporation achieved more effective use of XR technology by using BIM/CIM models for each work step.The Ministry of Land, Infrastructure, Transport and Tourism (MLIT) is promoting the use of ICT and BIM/CIM under the i-Construction*2 program, which aims to improve labor productivity by 20% by FY2025. [Link]

Related Products & Services

DataMesh Director (SaaS/On-Premise)

DataMesh Director is an enterprise level mixed reality design and collaboration platform. It provides great features like CAD import, fast storyboard creation, layout design, MR cloud, multi-user collaboration and presentation. It can also be integrated with DataMesh DataMix knowledge graph to provide Mixed Reality training and guidance in real-time.

DataMesh Simulator Platform

Based on a solid 6-DOF motion platform and DataMesh Digital Twin services, , DataMesh Simulator Platform enables heavy equipment manufacturers to create full expereience training simulators with ease.